Scan-Xpress provides high-precision 3D scanning services using our dedicated GOM scanners at any location across Australia and New Zealand. Our team will travel to your location; capture 3D data of your required component, assembly or structure and support you to ensure you obtain the best result possible for your project or application.

Applications

Obtaining accurate 3D measurements of a physical part has many potential applications. Here are some reasons you would consider using this service:

- Quality-control of a manufactured part;

- Obtaining accurate dimensions of a prototype;

- Reverse engineering or competitor product analysis;

- Re-creating manufacturing data for an obsolete part;

- Creating 3D models and performing simulations or analyses.

Process

We travel to your location

We perform the 3D scan

Our team processes and delivers the scan data

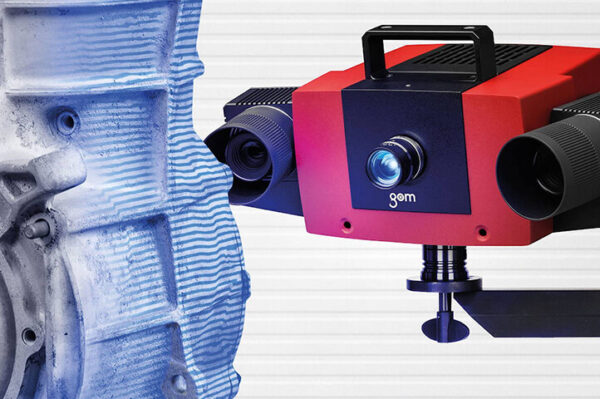

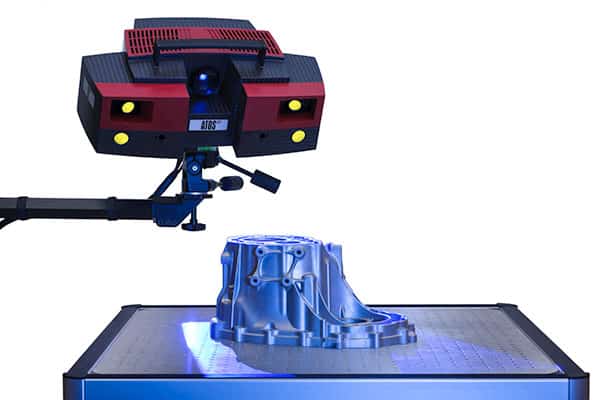

Dedicated Metrology Tools & 3D Scanners

Our team is equipped with a number of optical metrology tools and 3D scanners in-house to deliver you the best precision data for your part size and needs. Browse through our available systems below.

Versatile scanner offering a scalable field of view for medium to large objects.

Deliverable File Formats

The 3D scan data collected can be output in a mesh STL file format or as a raw point ASCI file format.

Alternatively, we offer comprehensive reverse engineering, inspection and analysis services for those looking to create working 3D CAD models or have our team perform specific analyses with the scan data.

Mobile 3D scanning services: Notable Past Projects

Using the T-SCAN Hawk, we performed a historical archiving project using 3D scanning for the New South Wales Government. We were able to capture a full 3D render of the ‘Sacrifice’ Anzac memorial sculpture.

Our team performed 3D scanning and reverse engineering on several Autonomous Underwater Vehicles for an Australian defence application. The T-SCAN Hawk was selected, due to its ability to accurately recreate 3D models of existing prototypes.

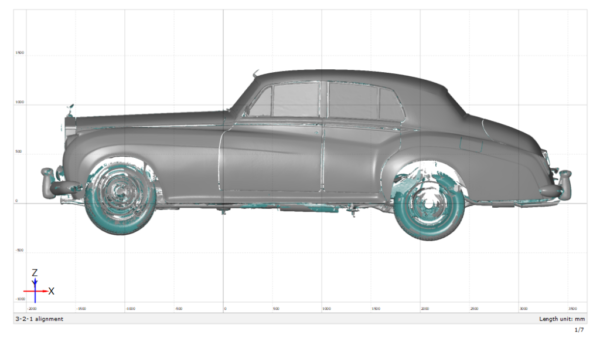

Our team 3D scanned a 1960 Silver Cloud Rolls Royce across 3 days in NSW. The project intent was to bring the vehicle back to life by upgrading a few of the exterior aesthetics as well as introducing better braking and handling performance.

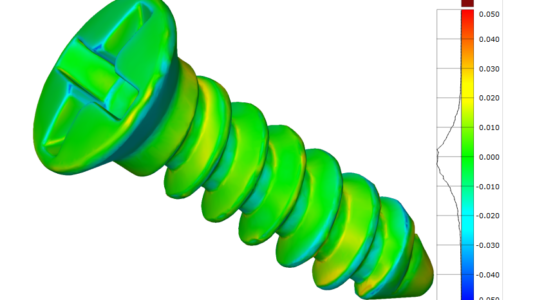

MAXONIQ, a company specialising in the design and manufacture of medical devices and surgical implants; contracted Scan-Xpress to 3D scan and reverse engineer a series of small surgical screws.