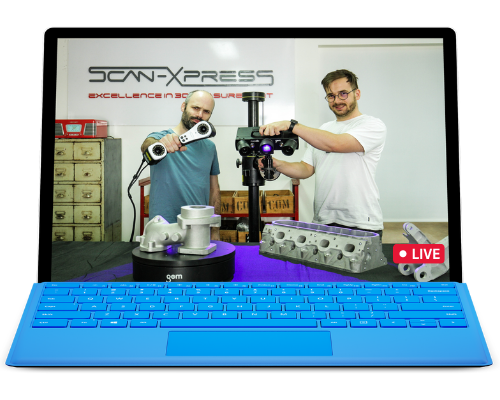

3D Scanners

Our range of precise 3D scanners and optical metrology systems help you perform quality inspection or reverse engineering tasks while reduce inspection times, detect more defects and digitize your results.

CMM & Vision Measurement

We offer the full range of ZEISS coordinate measurement, vision and multisensor machines providing you with best in class precision for quality inspection applications with tight tolerances and accuracy requirements.

Handheld Metrology

We offer mobile solutions with GOM handheld 3D scanners and Third Dimension’s Gap Gun. These systems help you capture great data and perform quality inspection or reverse engineering tasks anywhere.

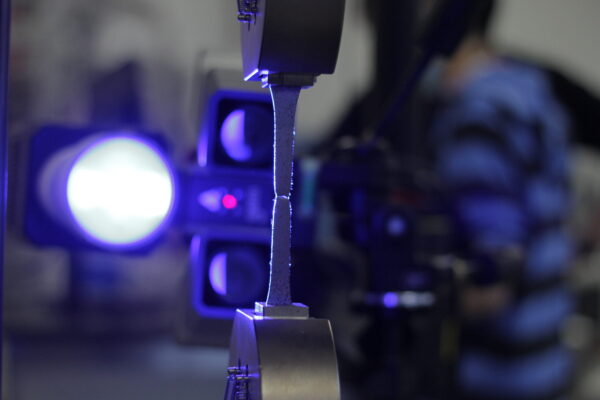

Digital Image Correlation

We provide DIC systems for applications materials testing, impact testing and ballistics. Camera systems come integrated with GOM Correlate software for comprehensive reporting and analysis.

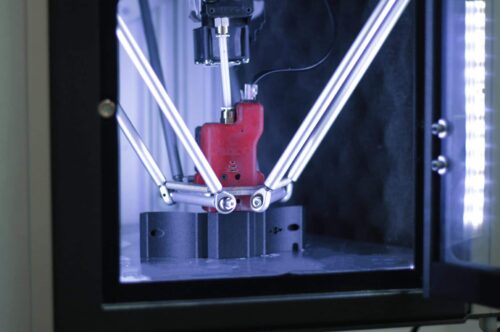

Metrology Automation

Complement your GOM optical sensor or ZEISS CMM with automation solutions enabling to perform in-line inspection with greater speed and achieve a high degree of manufacturing precisions and repeatable quality results.

CT & X-Ray

Measure, analyse, and inspect hidden defects and inner structures non destructively using ZEISS Computer Tomography and X-Ray measurement machines.

WASP 3D Printers

We are the exclusive Victorian reseller of WASP 3D printers offering best-in-class printing times coupled with huge printing volumes and controllable environments.

AESUB Scanning Spray

We are the exclusive distributor of AESUB Scanning Sprays for Australia and New Zealand. These products are designed to help acquire data on problematic surfaces using any 3D scanner or optical CMM.

Metrology & Quality Inspection Product Stories

Quality Inspection of Marine Propellers using the ATOS Q

One of our prospective customers is looking to use 3D scanning for quality control & reverse engineering of marine propellers. In this short video, we demonstrate how the ATOS Q scanner can be used to provide full field 3D data capture enabling us to compare to CAD and identify more defects.

ARAMIS for Material Testing at Deakin University

One of our long time partners – the Deakin University Institute for Frontier Materials (IMF) – recently purchased a second ARAMIS 3D camera system to use for digital image correlation (DIC) in their state of the art materials testing facility. Watch the video for full details on this story.

ATOS Q use in Turbine Machinery MRO

Meet Johan, director of Energetic Machinery in Belgium, and his passion for industrial steam turbines. The successful implementation of reverse engineering at his company allows Energetic to offer customers a complete service. Check out their story.