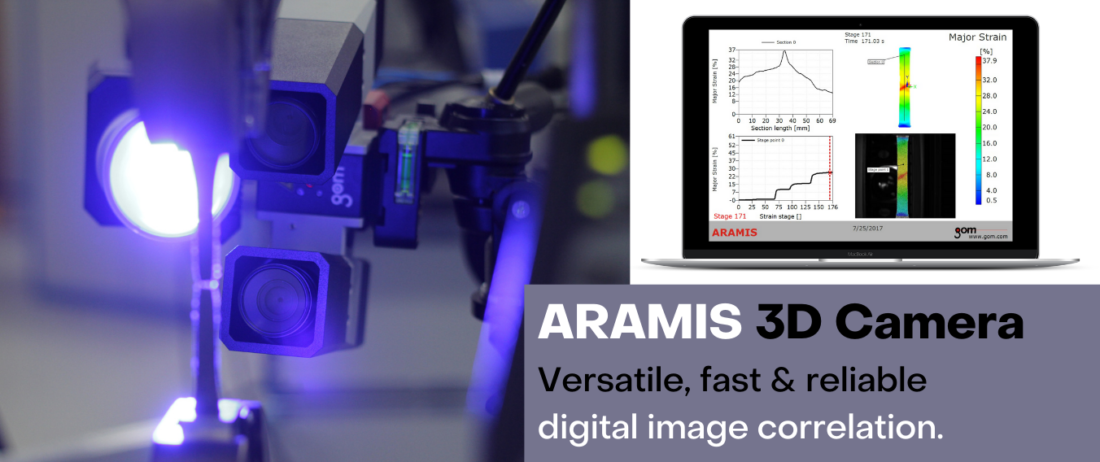

The ARAMIS system is a non-contact and material-independent measuring system based on digital image correlation and photogrammetry. It provides full field analysis for motion tracking, material property testing and deformation testing. This measurement solution is designed for research & development applications in any industry where materials, structural or motion analysis is required.

Overview

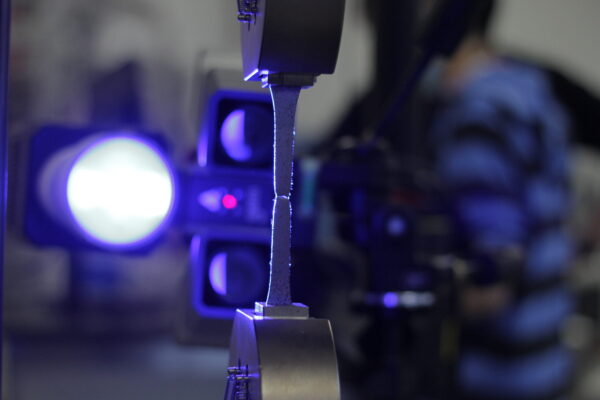

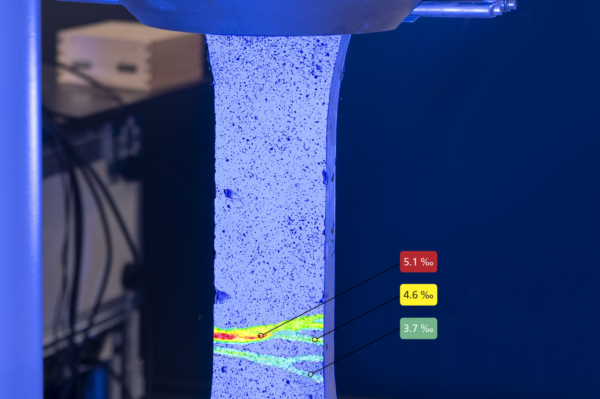

Materials Testing

ARAMIS coupled with GOM Correlate software uses automated pattern detection and camera triangulation to capture stress, strain & deformation data for material testing applications.

Motion Tracking

ARAMIS can track individual points or entire object motion allowing dynamic analysis and testing for deformation, biomechanics, motion/crash testing, impact testing & more.

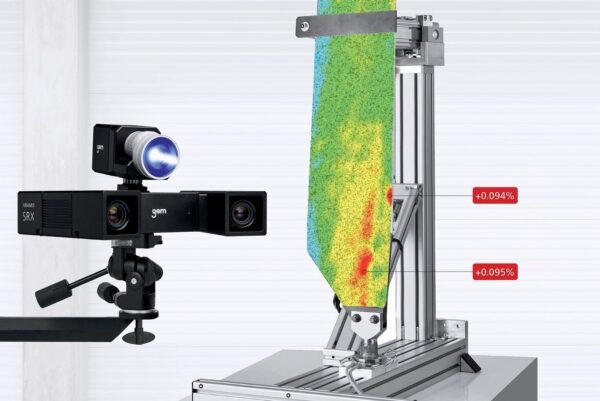

Digital Image Correlation

ARAMIS uses DIC to map 3D coordinates and evaluate displacement and strain data on the surface of measured samples. Applications include materials research, component testing, system dynamic analysis and much more.

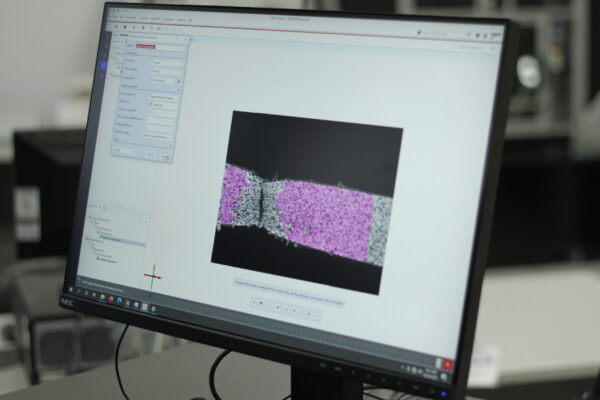

Integrated Software

ARAMIS 3D cameras are fully integrated with GOM Correlate software which enables full-field image analysis down to sub-pixel accuracy. The software is highly intuitive & automatically computes point or area positional changes and much more.

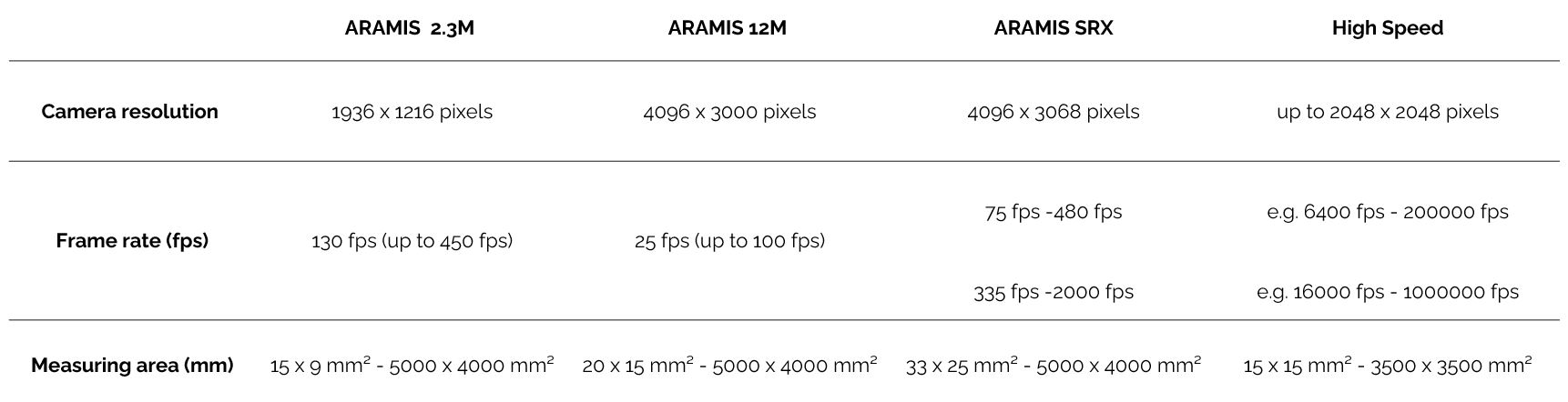

Technical Information

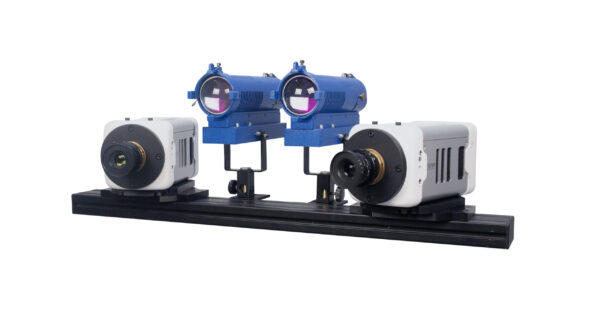

ARAMIS Fixed 3D Camera

The ARAMIS fixed system is built for applications requiring an easy-to-use and quick turnaround solution. Due to its seamless, robust frame, it is well suited for industrial applications.

ARAMIS Adjustable System

ARAMIS adjustable is intended for skilled users that are looking for a flexible solution enabling multiple camera and measuring volume changes.

Featured Applications

ARAMIS at Monash’s Drop Weight Testing Facility

We supplied Monash University with an ARAMIS system enabling them to perform testing for materials research and development purposes.

Automotive Testing using ARAMIS

Watch this short video to see how high-precision measurement data can be used for automotive suspension simulation & analysis.