Scan-Xpress offers a wide range of services for engineering, design, architecture, manufacturing and quality control applications. We can help you design, measure, test and manufacture your next idea. Armed with best-in-class 3D Scanners and 3D printers our team will help you realise your project or business ambition.

Send us your part and we will perform a precise 3D scan in the Scan-Xpress studio providing you with an STL digital twin.

Based on the 3D scan data we collect, we are able to provide you with a 3D CAD model in the format of your choice.

Our team and equipment is mobile! We come to you and perform 3D scans in person, at your convenience.

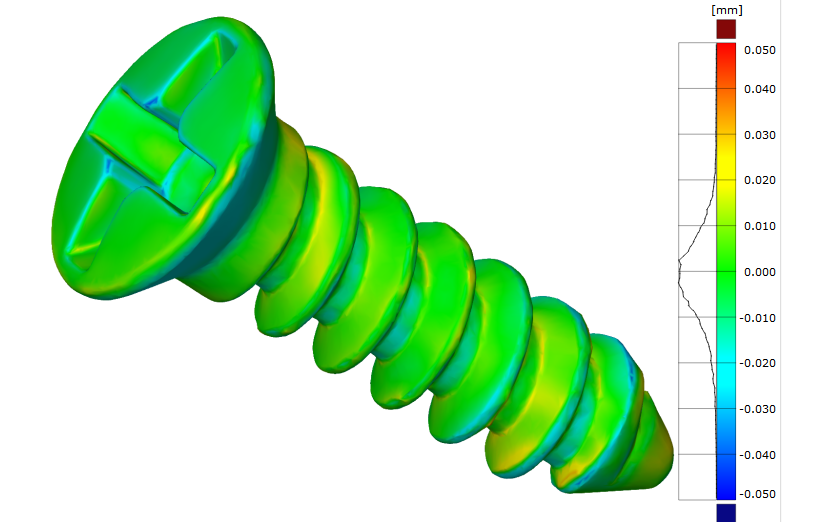

By comparing 3D scan to CAD data, we can provide you with valuable design & quality inspection information.

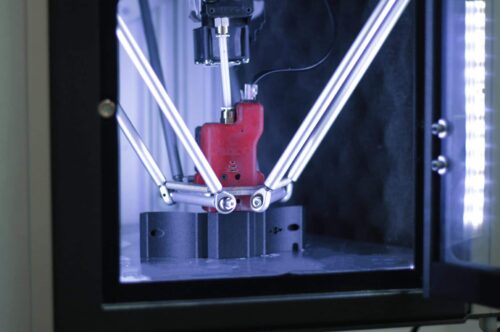

Provide us with a sketch, physical part or CAD data and we will work with you to bring your vision to life using our WASP 3D printers.

Meet with our team to discuss your project, create a new design or request a demonstration of our technology.

We performed a proof of concept for a potential customer demonstrating the capabilities of optical metrology for quality control & reverse engineering applications.

We designed and prototype a coffee cup for a Melbourne based start-up. We used our in-house 3D scanners and printers for this project.

We performed a historical archiving project using 3D scanning for the New South Wales government. We were able to capture a full 3D rendering of the ‘Sacrifice’ Anzac memorial sculpture.

Using 3D scanning, we created accurate CAD models and performed analyses on a series of small surgical screws used for surgical implant applications.