The GOM Scan 1 is the latest addition to the #HandsOnMetrology platform. It is a compact and mobile 3D scanner enabling digital object capture and achieving precise 3D meshes without breaking your budget. It is intended for designers, manufacturers and industrial users looking for a simple and affordable solution. Its main areas of application include quality control, reverse engineering and additive manufacturing.

Overview

Powerful 3D scanner

GOM Fringe Projection & Blue Light Technology enables precise mesh capture in every-day business environments. It comes in 3 measuring volumes and captures 6 million points per scan.

Small, mobile & intuitive

Weighing in at only 2.5 kg and packing into a robust easy to carry case, it is the perfect solution to take on the road or for versatile businesses. It is easy to use and requires minimal training.

Software that guides you

Gom Scan 1 operates with GOM Inspect providing powerful mesh editing functionalities, an intuitive workflow assistant, and task automation to speed up your process.

Tools to support you

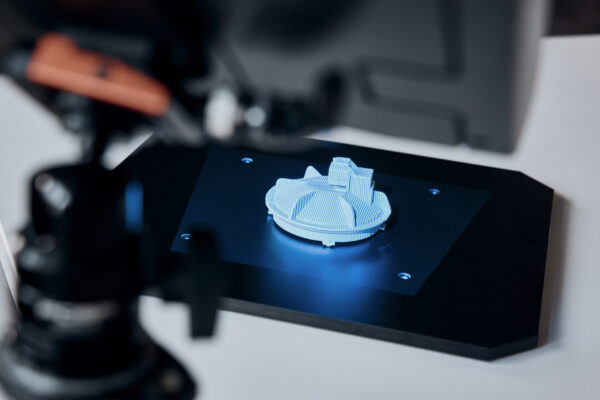

Use the portable desk stand or tripod to mount the scanner. Combine with the GOM ROT 350 automated rotation table to save time and improve your workflow.

Technical Specifications

| GOM Scan 1 (100) | GOM Scan 1 (200) | GOM Scan 1 (400) | |

| Points per scan | 6 million | 6 million | 6 million |

| Point distance | 0.037 mm | 0.060 mm | 0.129 mm |

| Measuring area | 100 x 65 mm² | 200 x 125 mm² | 400 x 250 mm² |

| Working distance | 400 mm | 450 mm | 500 mm |

| Light source | LED | LED | LED |

| Weight | approx. 2,5 kg | approx. 2,5 kg | approx. 2,5 kg |

| Dimensions | 290 x 215 x 80 mm³ | 290 x 215 x 80 mm³ | 290 x 215 x 80 mm³ |

| Cable length | 5 m | 5 m | 5 m |

| Connection | USB 3 | USB 3 | USB 3 |

| Operating system | Windows 10 | Windows 10 | Windows 10 |

| Software | GOM Inspect | GOM Inspect | GOM Inspect |

Featured Applications

Using the GOM Scan 1, we performed a 3D scan of a classic Ford Falcon hood scoop. We reverse engineered and modified its geometry and length to allow our client to add some power to his engine.

Using the GOM Scan 1, AESUB & Delta WASP 3D printers; we scanned, reverse engineered and manufactured a complex object, showcasing how 3D scanning & 3D printing can be used to solve design & manufacturing problems.

Project Highlight: Cowboy E-Bikes

Meet Olivier from E-bike manufacturer Cowboy in Brussels. GOM Scan 1 helps Cowboy e-bikes with creating of perfectly flush frames, and in designing and measuring complex assemblies.