Geomagic Design X is a purpose built reverse engineering software capable of converting 3D scan data into high quality CAD models. By solid model extraction functionality, accurate surfaces can be fitted precisely to high resolution 3D scans, as well as adjustments in mesh editing and point cloud processing. This allows for the reverse engineering of any parts and creation of high quality designs ready for all modes of manufacturing.

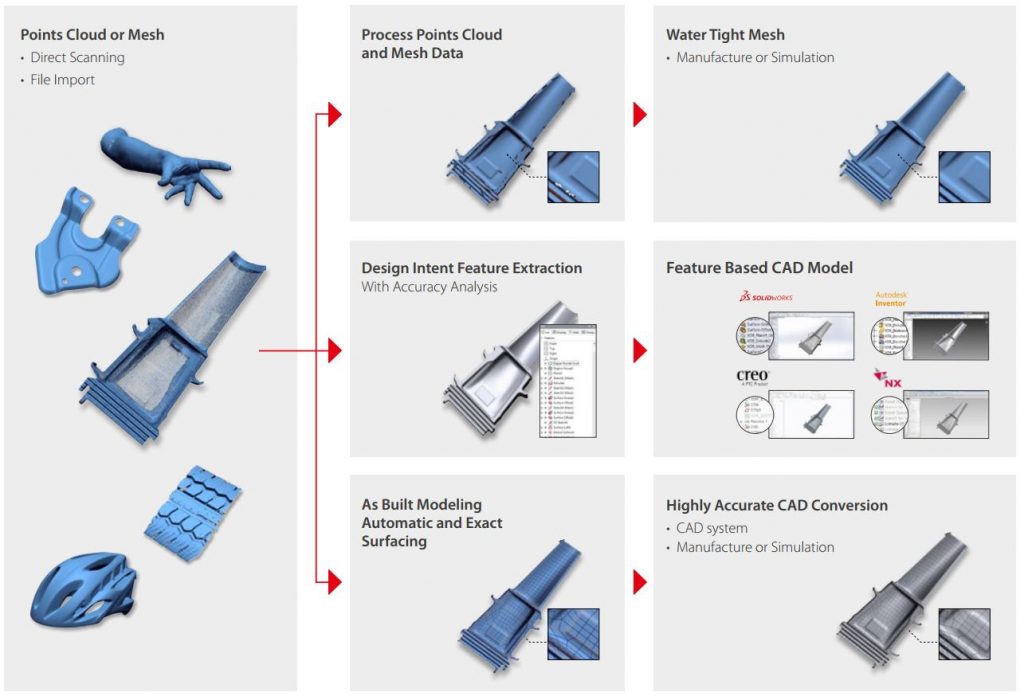

Workflow

Software Benefits

Broaden Design Capabilities

Product design can start from real world existing products by modelling CAD from 3D measurement data. Geomagic Design X allows the creation of editable, feature-based CAD models from a 3D scanner and incorporate them into your product portfolio.

Enhance CAD Environment

By adding 3D scan data into your CAD environment the design process can be accelerated, whilst creating versatility in your capabilities. Geomagic Design X is software complementary with CAD platforms, with native output to Solidworks, Autodesk Inventor, Siemens NX, Pro/Engineer, PTC Creo and Solid Edge.

Accelerate Time to Market

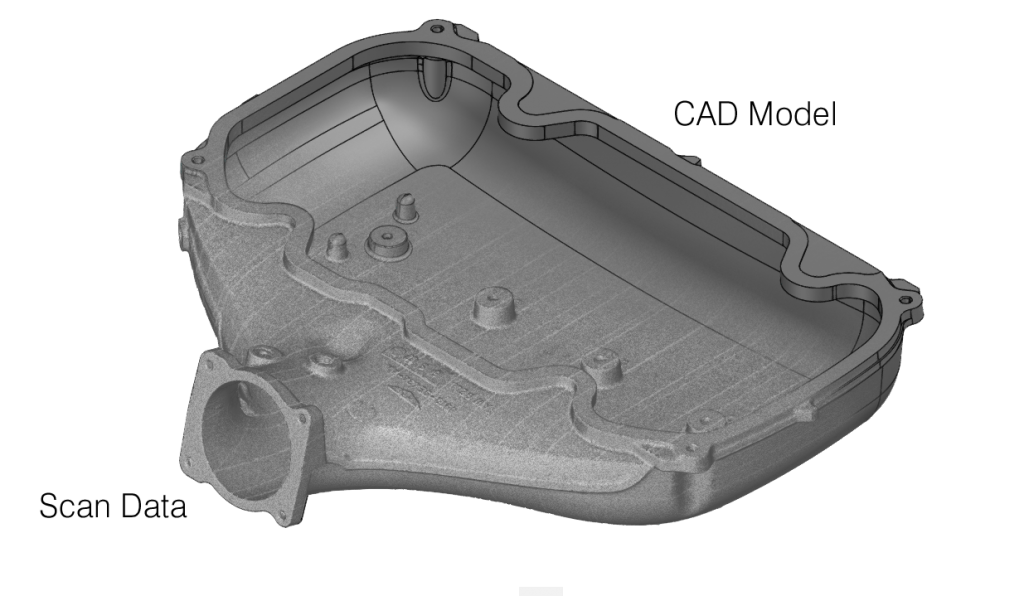

Shed up to weeks of time from generating the product idea to finishing the design. Using scan data gives the benefit of modelling complex parts that would take excessive time otherwise with conventional modelling from scratch.

Reduce Design Costs

Modelling with scan data can significantly reduce costs and time in the manufacturing process. Reduce tool iteration costs by using actual part geometry to perfect your CAD design and eliminate part springback. Costly errors such as poor fit of parts can be quickly adjusted to ensure maximum efficiency.

Leverage Existing Assets

Geomagic Design X provides the opportunity to digitally catalogue your parts. They can be refined, improved, reused and redeveloped into new CAD data for production improvements.

Do the Impossible

Geometrically complex parts with high constraints and tolerances can now be reproduced with high accuracy and ease. Create components that can integrate with already existing products, and recreate geometry that cannot be measured in any other way.

Geomagic Design X Features

• Full integration with Geomagic Capture Scanners

• Supports import of over 60 file formats including polygons, point clouds and CAD

• Expertly handles massive mesh and point cloud data alignment, processing and refining, mesh construction

• Easy-to-use mesh repair tools deliver rapid hole filling, smoothing, optimizing, rewrapping and polishing tools such as Smart Brush.

• Automatic, feature-based solid and surface extraction direct from 3D scans

• Rapidly creates solids or surfaces like you would in CAD

• Automated Accuracy Analyzer™ tools compare and validate surfaces, solids and sketches against original scan data

• Live Transfer™ supports the output of data to the industry’s leading CAD systems

• Industry-leading Exact surface creation converts organic shapes to precise CAD models

• Supports comprehensive export of neutral CAD or polygon files

• Instantly create stunning renderings of your designs in Keyshot