Having a robust and efficient quality control process is critical for success in Australia’s manufacturing industry. Whether you are producing consumer goods or high-precision parts, we provide you with the solutions and services to perform inspection and analysis, quickly and efficiently.

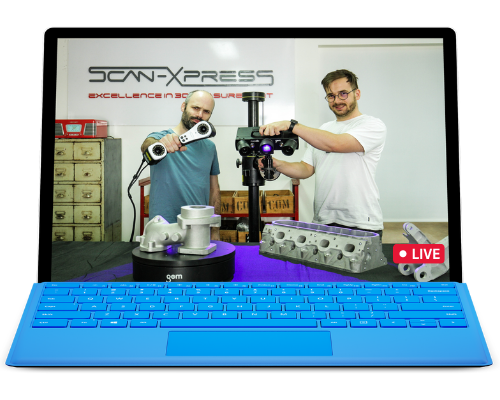

Our team of metrology experts and engineers are dedicated to helping you reach your business goals. Below, you can find out how Scan-Xpress can help you to detect more defects, improve inspection speeds and eliminate waste.

Having the right metrology tool is the first step for successful quality control. Our team will help identify the system or solution that will offer you the precision and efficiency you need. We provide turnkey solutions which include hardware, software, commissioning, training and on-going support.

Using optical 3D Scanners such as the above ATOS Q; you can achieve CMM level precision in a fraction of the time. Integrating optical metrology in your production line will help you remove process bottlenecks, while ensuring a high product quality and reliability.

Our portfolio includes high-precision measurement systems such as the GOM ATOS 5, as well as ZEISS CMMs which offer best-in-class precision. We also offer specialty products such as the GAPGun for measuring profiles, gap and flush and ZEISS CT/X-Ray machines for internal defect detection.

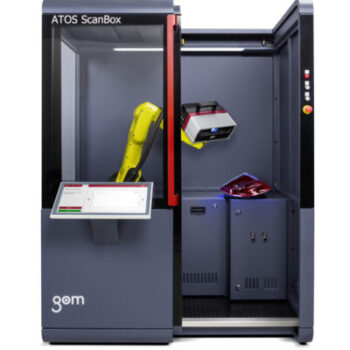

All of our systems are fully integrated with accompanying software which will help simplify your workflow and digitise results. We also offer a number of automation add-ons including automatic rotation tables, GOM ScanCobot robotic arm, and ATOS ScanBox which offers full automation and part handling.

Want to book a demo or discuss your project?

Featured Quality Control Applications

Amiga Engineering, an Australian-based precision machining & additive manufacturing company, was looking to improve its quality control capabilities having recently found their CMM system unable to perform certain critical operations.

One of our prospective customers was looking to use 3D scanning for marine propeller quality control and reverse engineering. We performed a proof of concept scan using the GOM ATOS Q 3D scanner to demonstrate the capabilities of optical metrology in this application.

Success Story: Toolcraft Additive Manufacturing

Toolcraft manufactures high-end precision parts using 3D printing, a modern process that represents a challenge for quality assurance. Watch the video above to see how Toolcraft Germany integrate 3D scanners, CMMs and X-Ray technology to ensure a high product quality and seamless processes.

Success Story: Volkswagen Quality Control

Volkswagen Commercial Vehicles in Wrzesnia, Poland inspects the all new Volkswagen Crafter vehicles using in-line, automated optical metrology systems. Watch the video below to see how the integration of optical metrology and robotics helps VW perform quality checks with speed and accuracy.