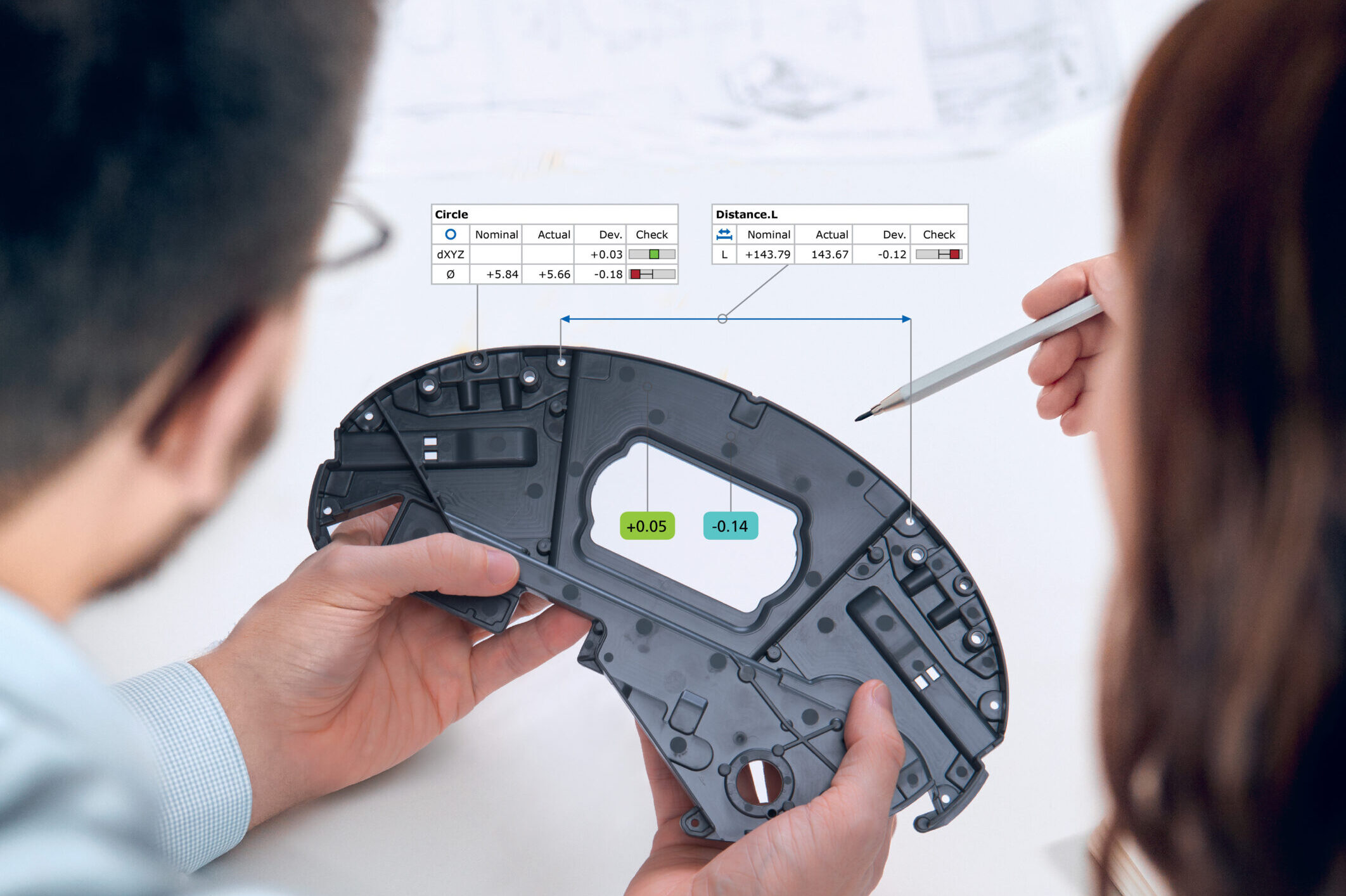

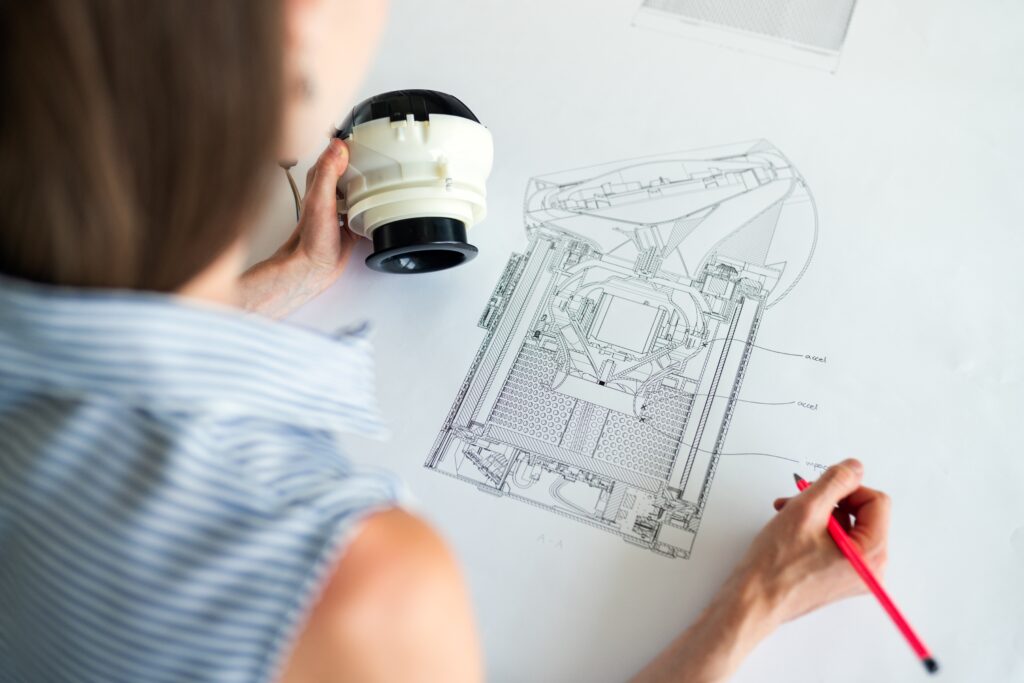

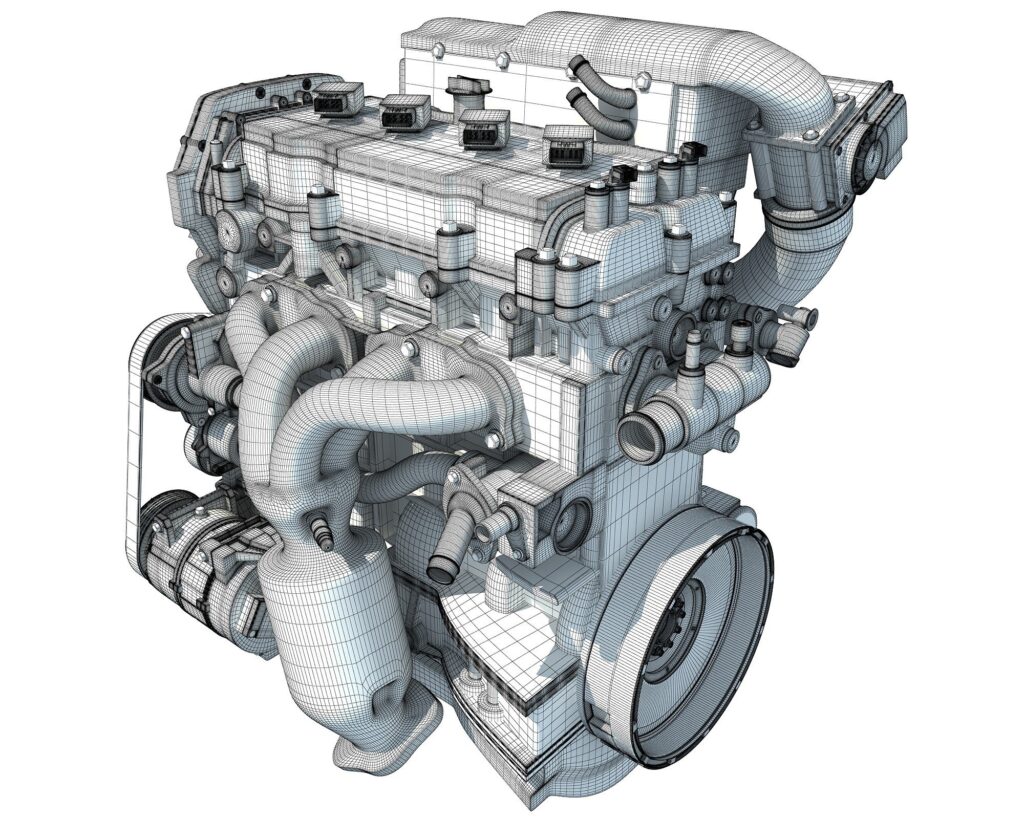

Scan-Xpress provides component and assembly reverse engineering services. By using dedicated optical scanners and state-of-the-art reverse engineering software, our team can create CAD models and drawings from any physical component provided.

Applications

Creating a digital twin based on a physical component or assembly has many uses in design, engineering and manufacturing applications. Here are some areas of application:

- Re-create manufacturing data for an obsolete part;

- Reverse engineering or competitor product analysis;

- Digital archiving;

- Perform simulations and analyses.

Process

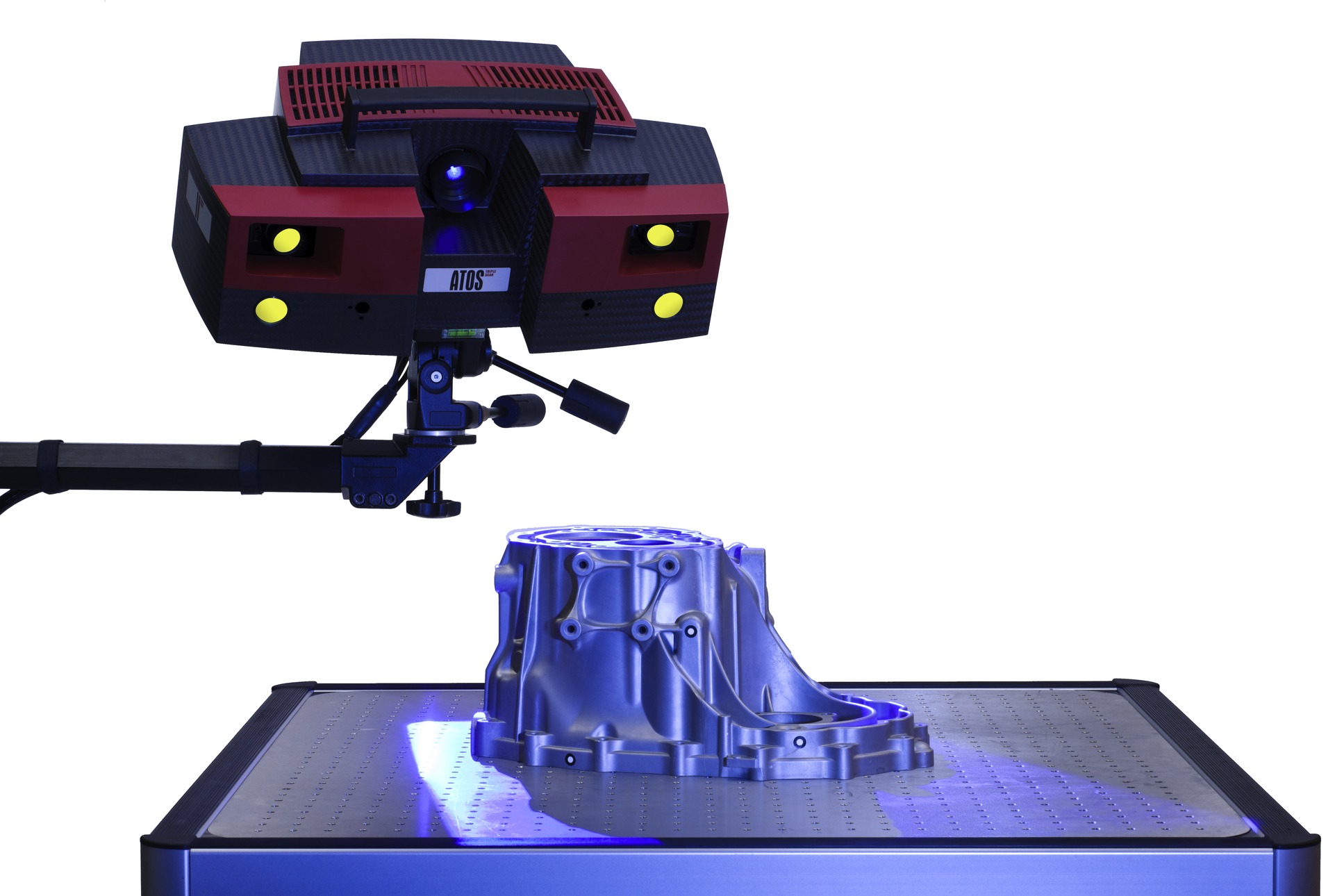

We perform a 3D scan of your object or you send us your data set

We perform data processing and digital twin creation

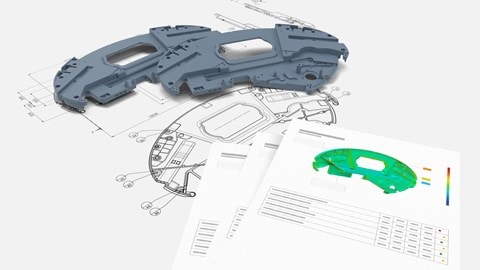

We deliver working 3D models and manufacturing drawings

Dedicated Scanners

Our team is equipped with a number of optical sensors in-house to deliver you precise models and drawings. Browse through our scanners below:

DELIVERABLE FILE FORMATS

Any raw data received or scan-data collected from your physical part, will be rendered into a 3D model then exported in the file format of your choice. We also have the ability to create manufacturing and assembly drawings.

Here are some CAD native file formats we commonly use:

- Geomagic Design X

- SOLIDWORKS

- CATIA

- Creo Parametric

Here are some 3D model transfer formats we often use:

- STEP

- IGES

- Parasolid

- AutoCAD DXF

Notable Past Projects

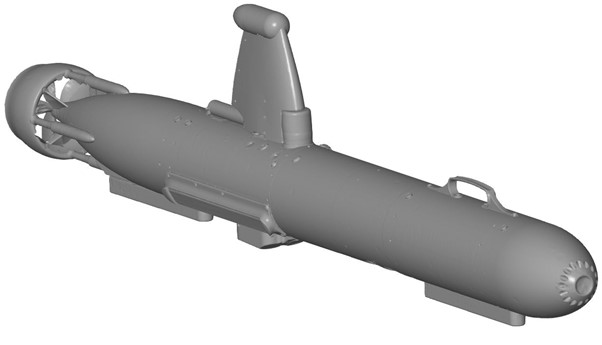

3D Scan & Reverse Engineering of Unmanned Underwater Vehicles

> Read more

The purpose of the scan was to accurately re-create 3D models of existing prototypes for use in computational fluid dynamic analysis testing and modelling.

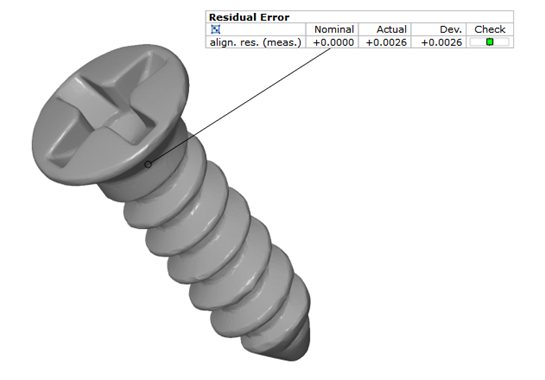

REVERSE ENGINEERING SURGICAL SCREWS FOR FEA SIMULATION & MEDICAL IMPLANT DESIGN

> Read more

MAXONIQ, a company specialising in the design and manufacture of bespoke cranio-maxillofacial surgical implants; contracted Scan-Xpress to produce accurate CAD models on a series of small surgical screws.