Scan-Xpress provides component, assembly analysis and reporting services to meet your project requirements. Our optical scanning systems allow us to perform full-field of view data capture; enabling us to perform analyses relevant for quality control, manufacturing, engineering and design purposes.

Applications

Due to our full-field data capture capabilities, we are able to perform many useful analyses of your parts and assemblies.

Below are some areas of application we can assist with:

- Manufacturing quality control and tolerance checks;

- Product wear and lifecycle analysis;

- Tool analysis and correction;

- Prototype and design optimisation;

- Simulations and Finite Element Analyses (FEA).

Process

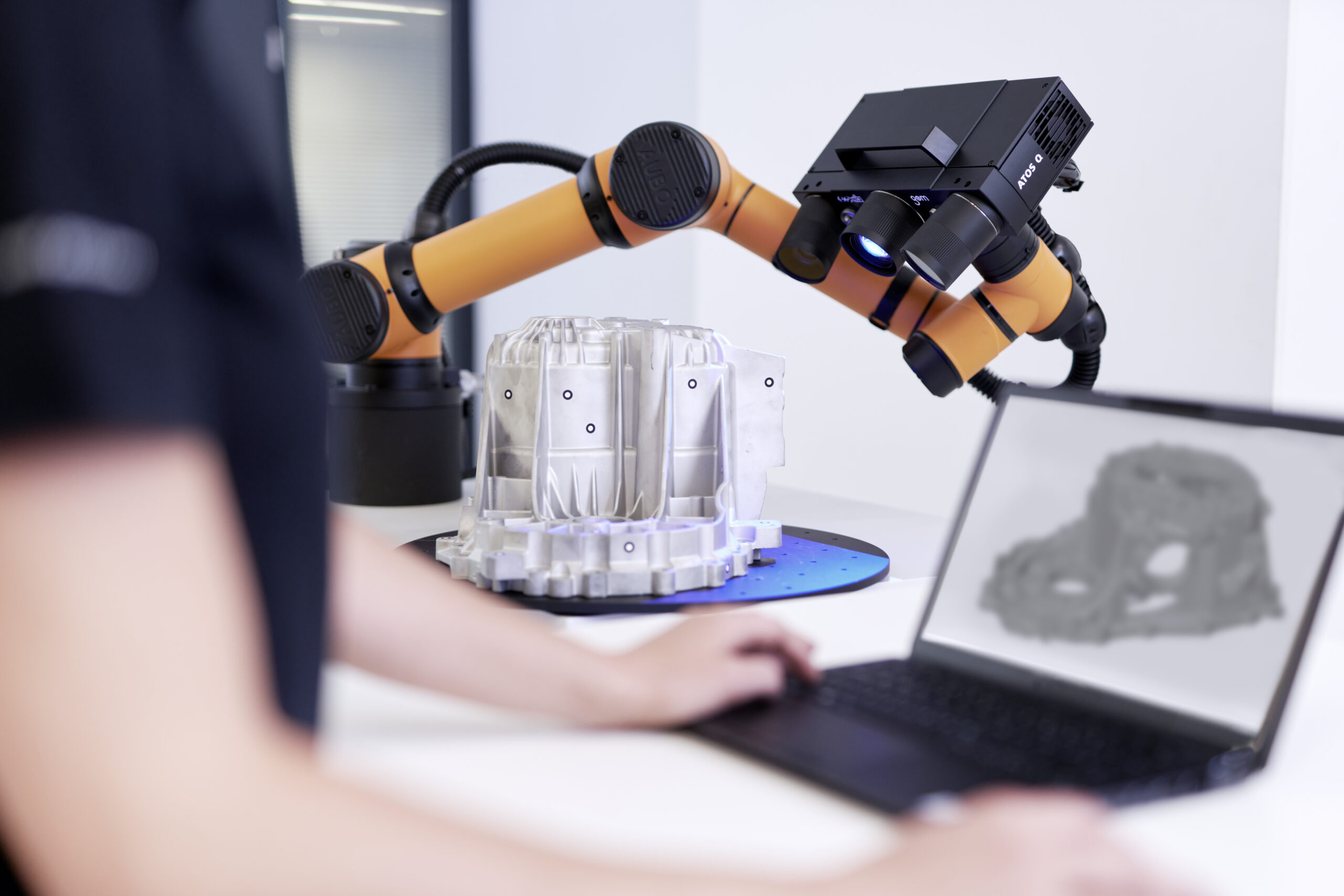

We perform a 3D scan of your object or you send us your data set

We perform data processing and digital twin creation

We deliver results and reports that are both simple and easy to use

Dedicated Scanners

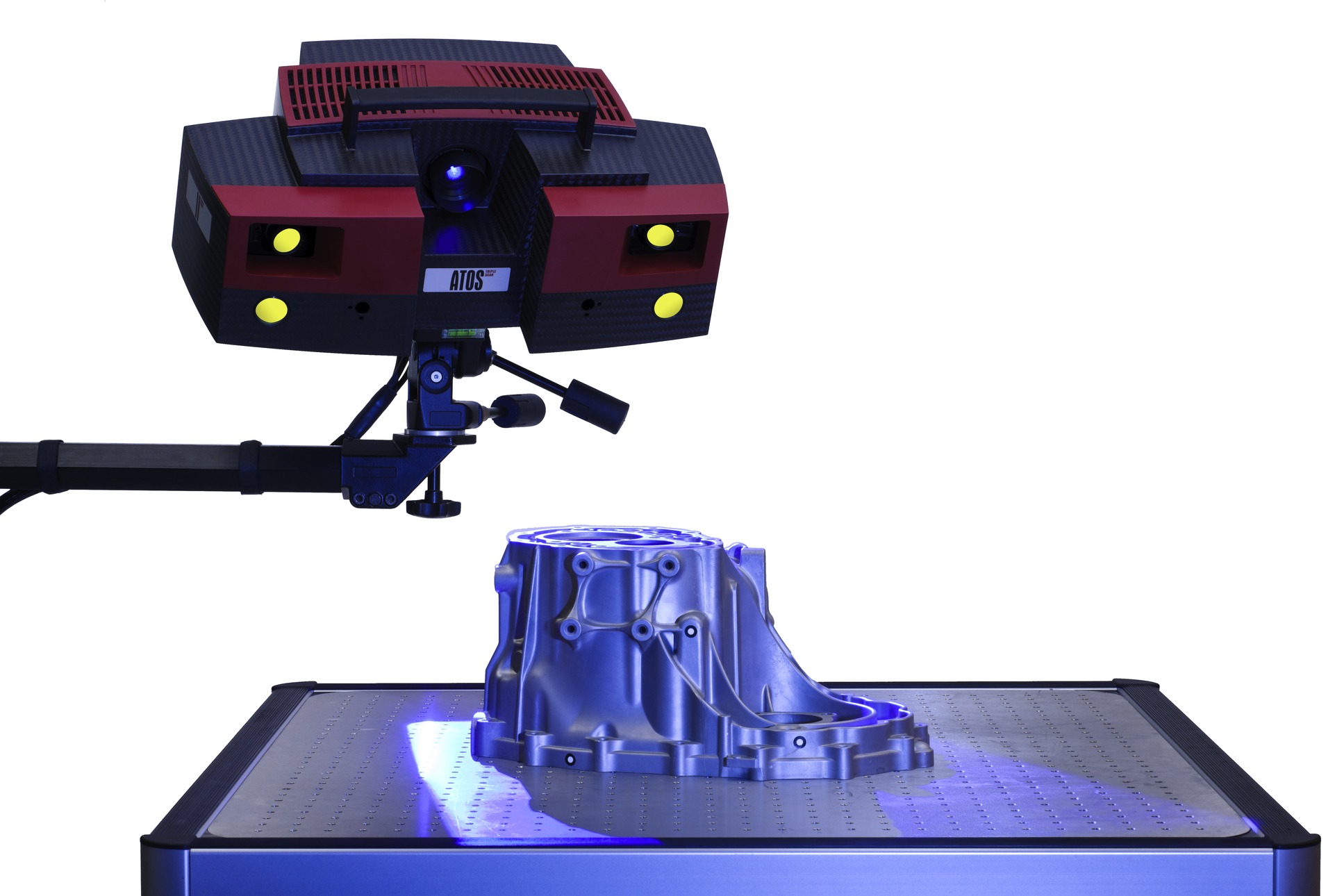

Our team is equipped with a number of optical sensors in-house enabling us to capture accurate surface data and perform detailed analyses. Browse through our scanners below:

DELIVERABLES

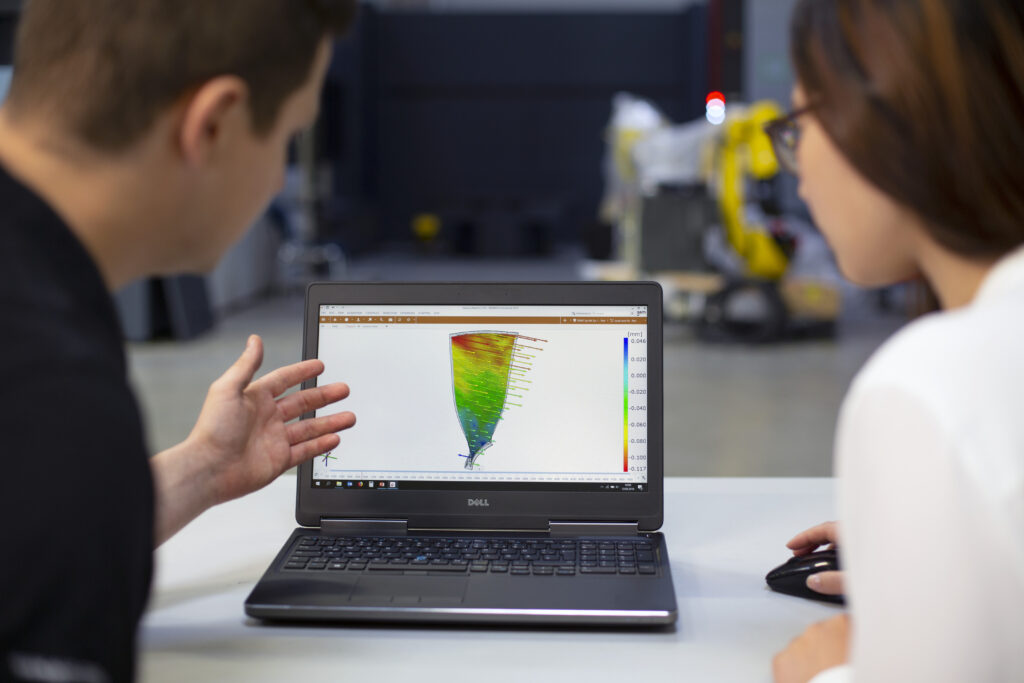

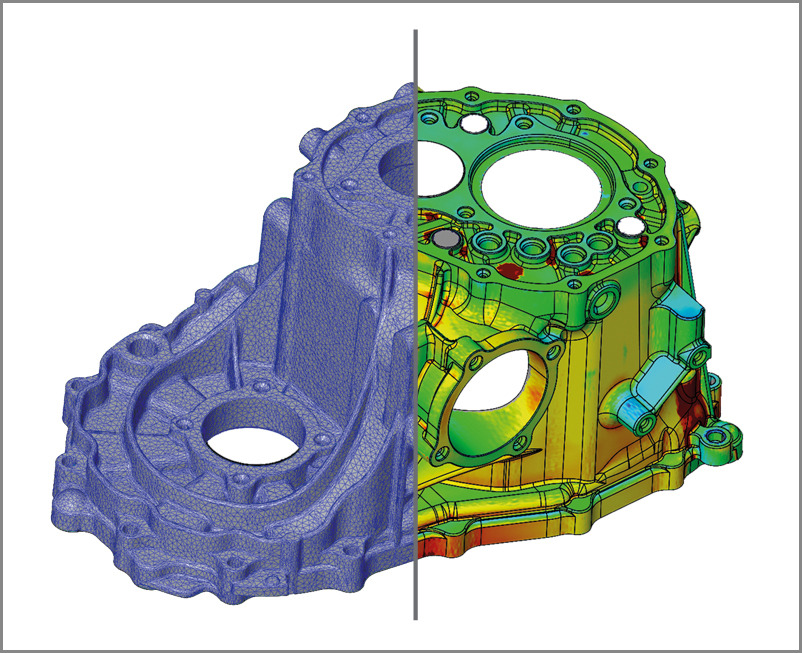

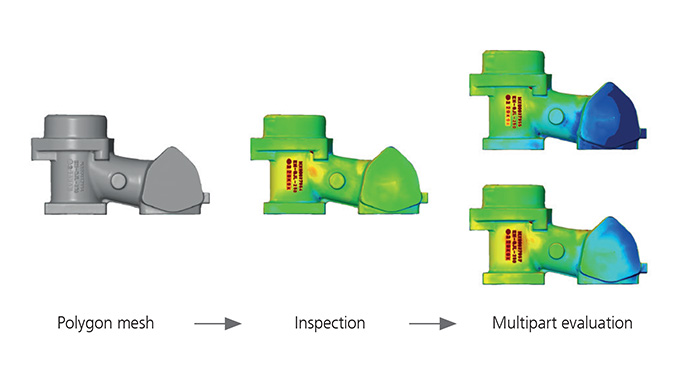

Due to the full-part capture capabilities of our systems, we are able perform analyses that would otherwise be impossible with traditional tactile metrology. Here are some analyses & report types we can create:

- Full field visual colour maps

- GD&T and dimensional Analysis

- 2D drawing & 3D CAD comparison & analysis

- Golden/average-mesh comparison & analysis

- CSV data ready for excel reporting

Notable Past Projects

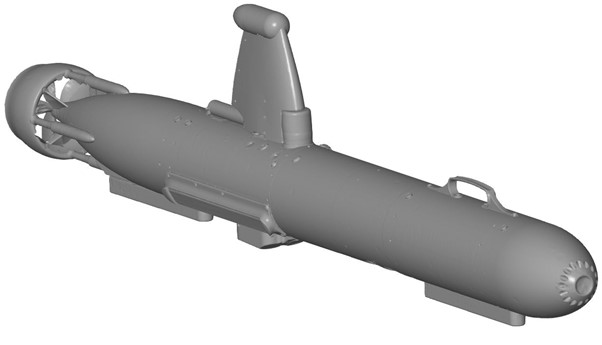

3D Scan & Reverse Engineering of Unmanned Underwater Vehicles

> Read more

The purpose of the scan was to accurately recreate 3D models of existing prototypes for use in computational fluid dynamic analysis testing and modelling.

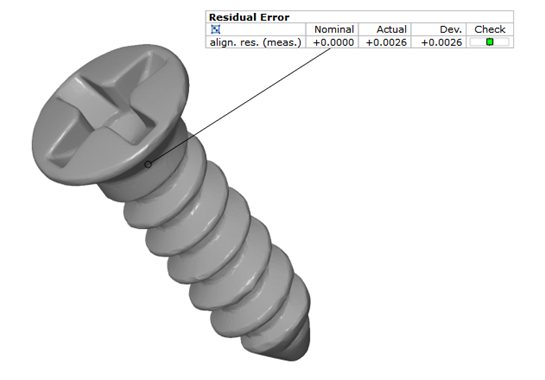

REVERSE ENGINEERING SURGICAL SCREWS FOR FEA SIMULATION & MEDICAL IMPLANT DESIGN

> Read more

MAXONIQ, a company specialising in the design and manufacture of bespoke cranio-maxillofacial surgical implants, contracted Scan-Xpress to produce accurate CAD models on a series of small surgical screws.