Overview

The AESUB range of 3D scanning sprays have been developed to help acquire data on problematic surfaces. These sprays will provide you with outstanding data quality after applying a thin, opaque coating to your part. You can use them in a variety of applications and with virtually any 3D scanner.

3D Scanning Applications:

- Scanning transparent or reflective parts

- Deep pocket or groove scanning

- High-accuracy requirements

AESUB Transparent

Scanning spray which matts surface’s with a transparent film. The transparent surface allows capture of the components colour information at the same time as the geometry. AESUB Transparent vanishes from the surface, which means no cleaning up.

Key Features:

- Transparent mattifying spray

- For scanning while also capturing colour information

- Ideal for photogrammetry, film, and photography

- Thin and homogenous coating of 10-20 microns

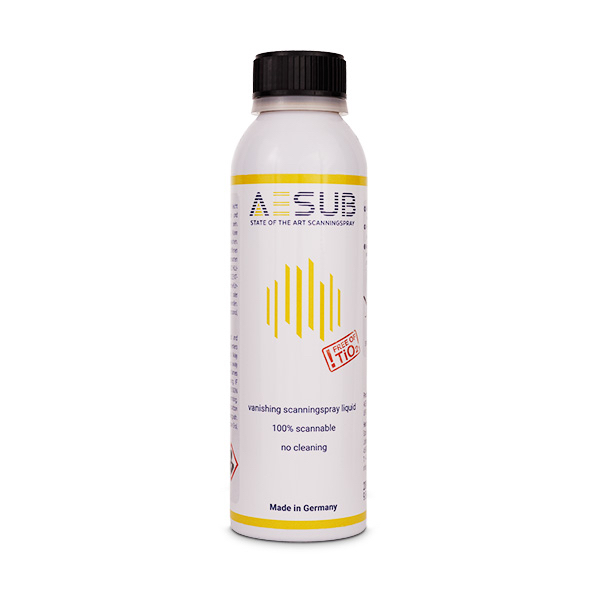

AESUB Yellow

Vanishing 3D scanning spray for use with an Airbrush system. Ultra-thin and homogeneous coating makes it ideal for very high accuracy applications. No clean-up required!

Key Features:

- For use with an airbrush system

- Coating thickness of 1 micron

- Perfect for very high accuracy scanning

- Free from pigments

AESUB Blue

Vanishing 3D scanning spray providing you with an ideal surface for 3D scanning and completely sublimating from your part after scanning – no clean-up required!

Key Features:

- Disappearing scanning spray

- Short-sublimation time (approx. 2-4 hours)

- Thin and homogeneous coating (approx. 0.01080mm)

- Free of pigments and titanium dioxide nano particles (TiO2)

AESUB White

Permanent 3D scanning spray providing optimal contrast resulting in superior data capture. However, the spray does not sublimate and does require part clean-up after use.

Key Features:

- Permanent scanning spray

- Thin and homogeneous coating (approx. 0.00120mm)

- Free of titanium dioxide nano particles (TiO2)

- Provides optimal contrast values and data quality

AESUB Orange

Vanishing, long lasting 3D scanning spray providing outstanding data quality. Its longer sublimation times makes it ideal for larger or more complex inspections.

Key Features:

- Vanishing scanning spray

- Long-lasting (approx. 12-24 hours)

- Thin and homogeneous coating (approx. 0.00580mm)

- Free of pigments and titanium dioxide nano particles (TiO2)

AESUB Green

Vanishing scanning spray which comes in a spray-gun compatible format. It is ideal for bulk and high throughput 3D scanning or quality inspection applications.

Key Features:

- Disappearing scanning spray in bulk/spray-gun format

- Short-sublimation time (approx. 4-6 hours)

- Thin and homogeneous coating (approx. 0.01080mm)

- Free of pigments

Featured Applications

Using the GOM Scan 1, AESUB & Delta WASP 3D printers; we scanned, reverse engineered and manufactured a complex object, showcasing how 3D scanning & 3D printing can be used to solve design & manufacturing problems.

We performed a 3D scan using the ATOS Q of a car headlight assembly. To deal with the transparent plastic and reflective surfaces, we used AESUB blue during the process and created this short video showcasing the USPs and vanishing time-lapse.

Scan-Xpress’s team performed a gear quality control test for one of our customers using AESUB Scanning spray in conjunction with the ATOS Q 3D Scanner to capture incredibly precise data.

Order Form

*Prices do not include GST or Shipping.

If you would like to place an order for a different quantity, please email info@scan-xpress.com.au

Want to become an AESUB reseller?

Scan-Xpress is now taking applications for AESUB re-sellers in Australia. Please send an email to info@scan-xpress.com.au and we will get back to you with a proposal.