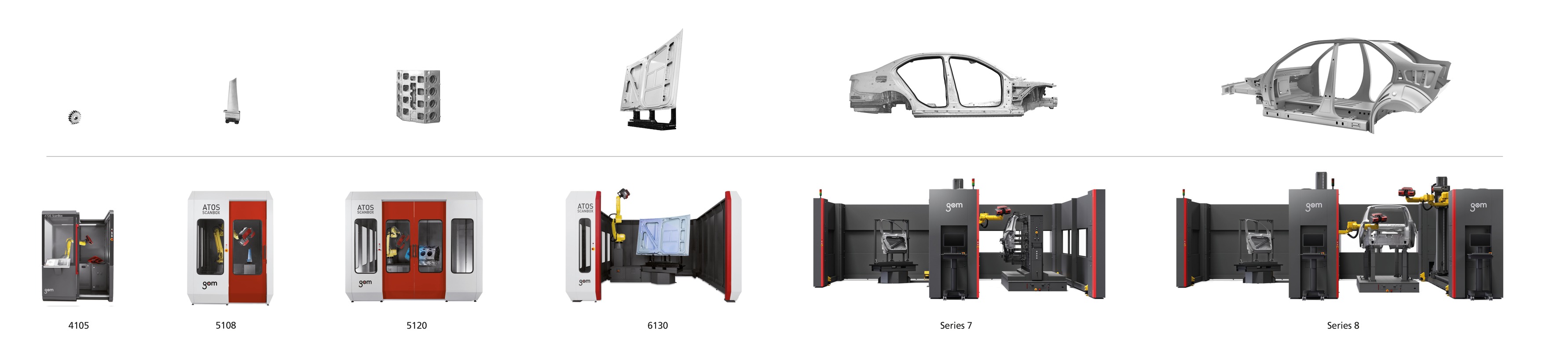

The ATOS ScanBox combines optical metrology, a multi-axial robotics, and advanced AI programming to provide the perfect blend of speed, automation and accuracy in quality assurance solutions. Available in 11 different variants for different applications and part sizes the standardized measuring machines offer an all-in-one solution for full-field 3D quality inspection, analysis and reporting.

Overview

The ATOS ScanBox series comes in a wide variety of shapes and sizes tailored to your specific application. It pairs with the following high resolutions 3D scanning systems: ATOS Q, ATOS Capsule, and ATOS 5. The ScanBox 4 and 5 are standalone, mobile systems that can be wheeled into place while the series 6 and above are floor anchored and built for in-line production integration.

Key Features

Pair with powerful ATOS 3D scanning sensors

ATOS 3D scanning sensors offer unmatched speed and resolution in optical metrology. The ATOS ScanBox series pairs with a wide selection of ATOS sensors allowing you to customize the measurement solution to your manufacturing application.

Backed by intuitive AI software

ATOS ScanBox uses intuitive GOM Suite and virtual measuring room (VMR) software to enable the user to work with the system without requiring specific robot programming skills. All robot movements are simulated and checked for safety before being performed in the actual environment.

Enabling efficient quality inspection

The ATOS ScanBox series is designed to help manufacturers streamline their operations by saving both time and money. They offer a perfect blend of speed & precision while smart software make them easy to integrate into existing processes or even allow for lights-out quality inspection with ScanBox BPS.

Chose the right ScanBox for you

The ScanBox series offers a wide variety of standardized configurations helping you select the ideal set-up for our application. ScanBox series 4 and 5 are portable and built for small component inspection while 6,7 and 8 enable large/heavy component and assembly inspection.

ATOS ScanBox Series Models

ScanBox Series 4

The compact ATOS ScanBox 4105 system allows for location-independent 3D inspection of small and complex parts up to 500 mm in size.

ScanBox Series 5

This mobile measuring system is designed for inspection of complex parts up to 2000 mm in size including turbine blades, blisks, and automotive & rail components.

ScanBox Series BPS

ATOS ScanBox BPS features autonomous loading/unloading and AI backed inspection enabling up to 11 hours continuous autonomous operation.

ScanBox Series 6

Automated shop floor metrology system developed specifically to reduce inspection times and minimize rework for parts up to 3000 mm / 5000kg.

ScanBox Series 7

Featuring 8-axis kinematics and very flexible sensor positioning, the Series 7 enables full-field analysis measurements of parts up to 10 meters.

ScanBox Series 8

Digitize and measure large and complex structures including car bodies, train components, and aircraft engines using 2 ATOS sensors mounted on 8-axis kinematics.

Want to book a demo or discuss your quality assurance needs?

Featured ScanBox Applications

ATOS ScanBox at Linde+Wiemann

Linde+Wiemann is an advanced steel structure manufacturer operating in Germany that has integrated the ATOS ScanBox into their production line to enable fast and precise quality assurance.

ATOS ScanBox Series 8 Overview

Check out this great video by our sister-company and partners in the US explaining the capabilities and applications of the ATOS ScanBox series 8.