The ZEISS Industrial Metrology range of CMMs offer unparalleled measurement precision and repeatability for a wide variety of applications. ZEISS CMM systems combined with GOM 3D scanners provide the perfect solution answering all your industrial metrology quality control & reverse engineering.

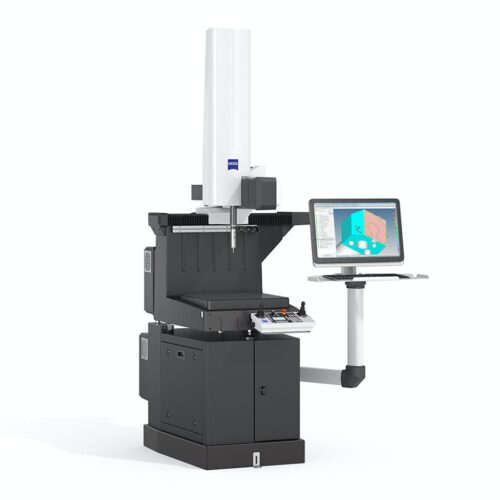

Product Highlight: CONTURA Multisensor CMM

Offering you unparalleled flexibility, speed and accuracy, the CONTURA line is the most versatile solution available on the Australian market. It can be equipped with 3 different sensor types; contact scanning, optical, and active scanning.

Product Highlight: DuraMax Shop-Floor CMM

The DuraMax offers the ideal shop-floor inspection solution due to a robust design and simple interface. It will help you digitise results, and replace manual gauges thereby increasing your end product quality and process repeatability.

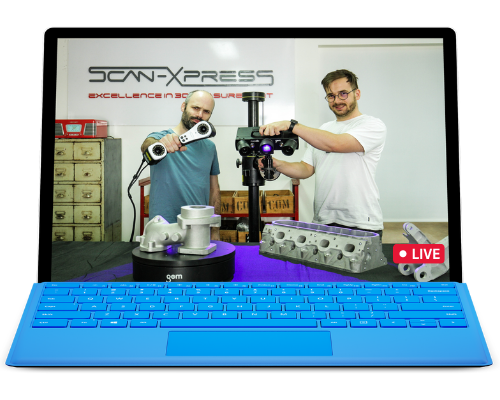

Solutions Overview: Webinar on ZEISS CMM workflows

Check out the webinar below providing a quick overview of ZEISS CMM solutions best suited for Australian industry as well as some key manufacturing examples. This will help you better understand how these solutions could fit smoothly into your manufacturing processes and help you increase your product quality while reducing errors and waste.

Bridge Coordinate Measuring Machines

Measurement results with high accuracy are particularly important for quality assurance. Bridge coordinate measuring machines from ZEISS offer a vast probe selection including passive tactile, active scanning and optical sensors.

Shop Floor CMMs

Shop floor CMMs deliver the flexibility and durability required to perform quality assurance and defect detection operations directly on the production floor.

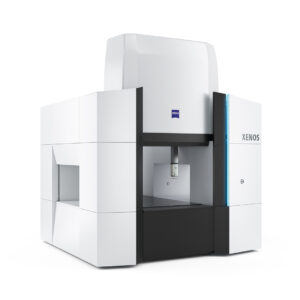

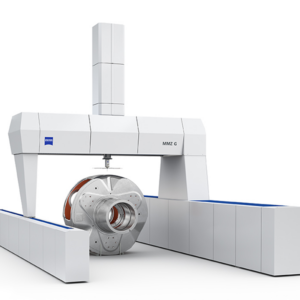

Large CMMs

Measure even the largest parts with highest precision with our selection of tabletop, bridge-type and gantry coordinate measuring machines. Each system can be tailor designed for your application, programmed and automated to fit with your production line and processes.

Horizontal Arm CMMs

Automated measuring solutions using multi-axial actuation and software integration to provide the highest level of precision and customizability. These solutions are fully designed and supported by the Scan-Xpress and ZEISS Australia teams and tailored to fit your high-end manufacturing needs.