Scan-Xpress provides cost effective, high-precision 3D scanning services using our dedicated in-house, GOM 3D scanners. Our team will support you to ensure that you get the best result possible, for your project or application.

Applications

Obtaining an accurate 3D scan of a physical part has many potential applications. Here are some reasons you would consider using this service:

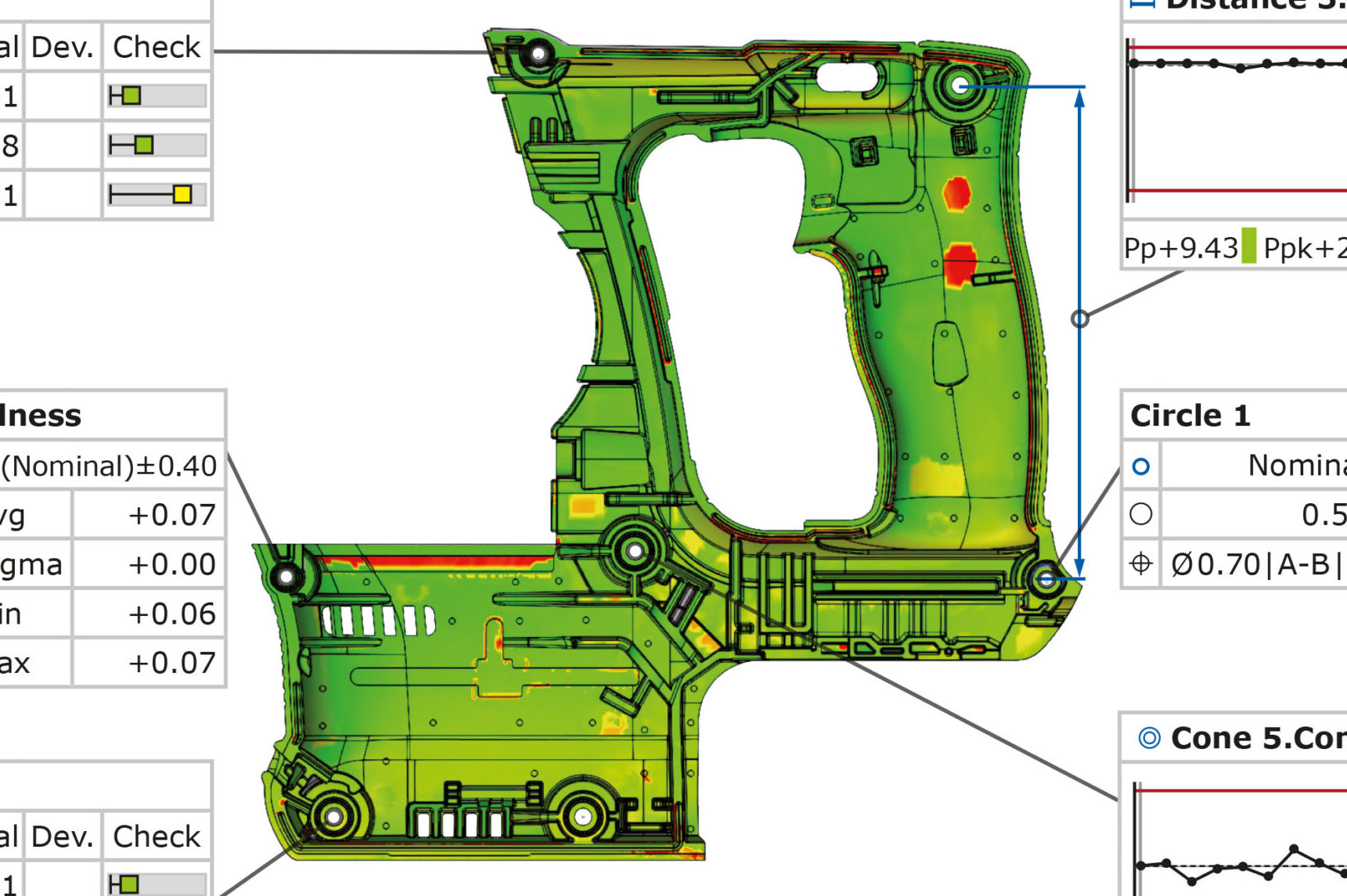

- Quality-control of a manufactured part;

- Obtaining accurate dimensions of a prototype;

- Reverse engineering or competitor product analysis;

- Re-creating manufacturing data for an obsolete part;

- Creating 3D models and performing simulations or analyses.

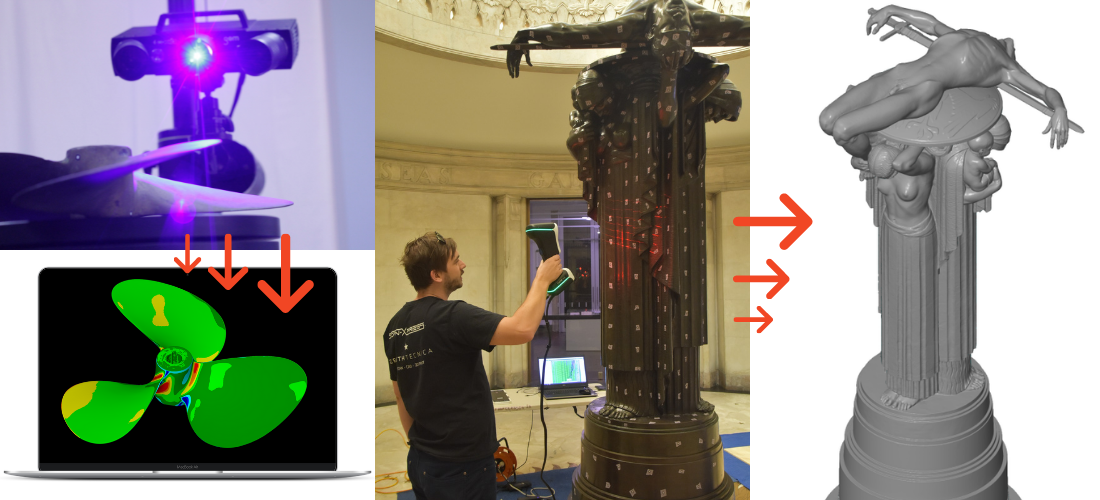

3D scanning process

Ship us your part

We discuss your project & needs

Our team performs a 3D scan

Our team processes the scan & sends your data

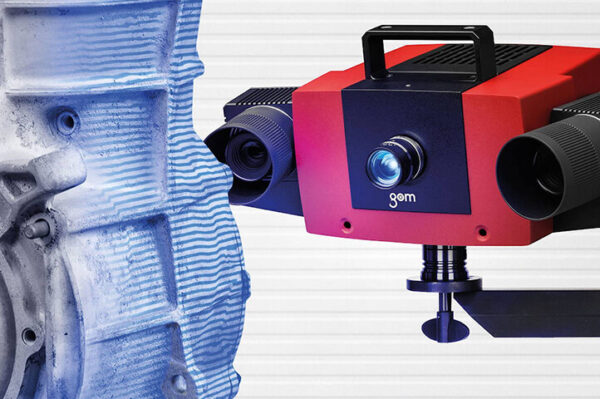

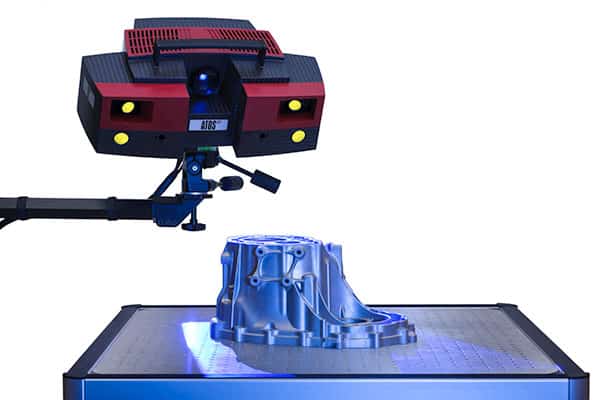

Dedicated Metrology Tools & 3D Scanners

Our team is equipped with a number of optical metrology tools and 3D scanners in-house to deliver you the best precision data for your part size and needs. Browse through our available systems below.

Versatile scanner offering a scalable field of view for medium to large objects.

3D scanning Deliverable File Formats

The 3D scan data collected can be output in a mesh STL file format or as raw point cloud ASCII file format.

Alternatively, we offer comprehensive reverse engineering and inspection and analysis services for those looking to create working 3D CAD models or have our team perform specific analyses with the scan data.

3D scanning services: Notable Past Projects

Using the GOM Scan 1, we performed a 3D scan of a classic Ford Falcon hood scoop. We reverse engineered and modified its geometry and length to allow our client to add some power to his engine.

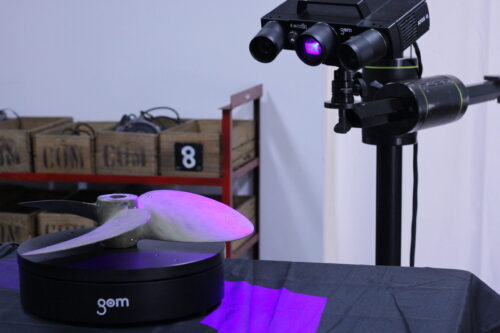

One of our prospective customers was looking to use 3D scanning for quality control and reverse engineering of marine propellers. We used the ATOS Q to capture full field 3D data enabling us to compare to CAD and identify critical defects.

Using the GOM Scan 1 and our WASP 3D printers, we performed a 3D scan, design and fast prototyping project for HopSkotch – a local Australian start-up. We delivered a minimal usable product in no time using these great modern tools.

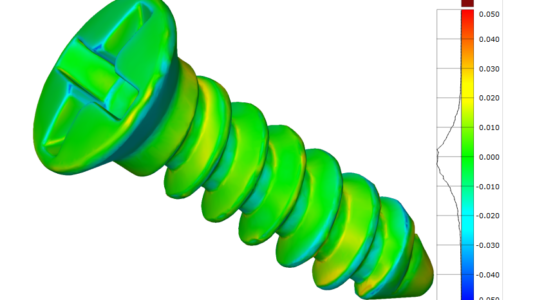

Maxoniq; a company specialising in the design and manufacture of medical devices and surgical implants, contracted Scan-Xpress to 3D scan and reverse engineer a series of small surgical screws.