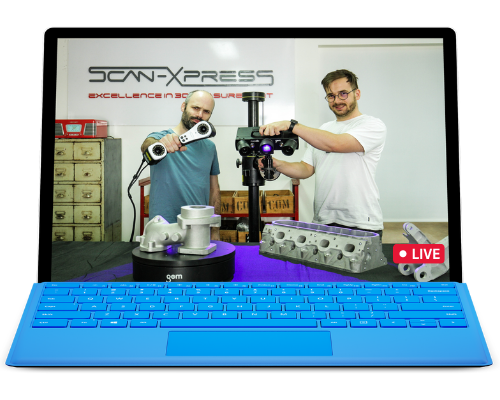

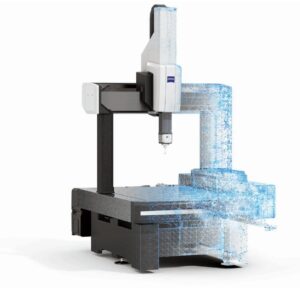

Scan-Xpress Metrology & Quality Inspection Solutions

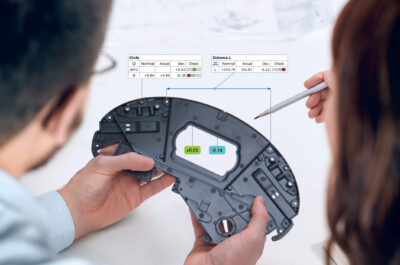

Scan-Xpress offers 3D metrology, 3D scanning, quality control, reverse engineering and inspection solutions across Australia and New Zealand. Our objective is to enable manufacturing industry growth by providing advanced tools, excellent knowledge and customer service.