Utilising modern metrology solutions, Scan-Xpress helps maintenance, repair and overhaul (MRO) service providers detect and analyse defects, digitise results and reverse engineer replacement parts. Having access to accurate tools enable you to capture full field 3D data, optimise MRO processes and ensure maintenance work is successfully performed to the required quality and tolerances.

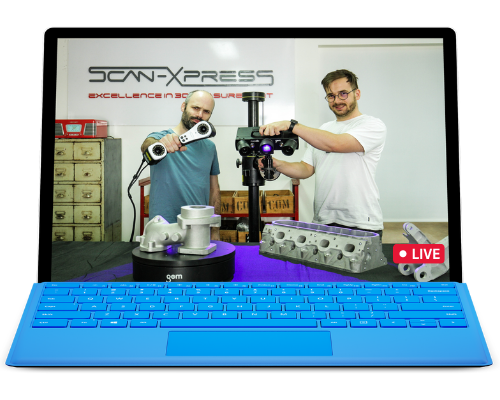

Below you can find out more about how Scan-Xpress can help detect and analyse wear defects, reverse engineer production ready CAD data and measure overhaul component quality.

Use 3D scanning to accurately measure components or assemblies, compare to CAD data and quickly detect defects. Optical metrology coupled with GOM Suite software offers benefits in time savings throughout your maintenance process.

Maintenance, repair and overhaul projects in industries such as mining, rail or aerospace often involve large components or assemblies. Use GOM photogrammetry systems such as TRITOP or T-SCAN Hawk to accurately measure even the largest objects.

Using GOM 3D scanners, you can capture 3D object data, detect defects and project them in real time directly onto the component using back projection! This allows for precise, fast and intuitive visual defect analysis by maintenance engineers.

Optical metrology coupled with ZEISS Reverse Engineering or Geomagic Design X software offers the capability to efficiently reverse engineer CAD data for defective or obsolete parts and quickly produce new designs and replacement components.

Want to book a demo or discuss your project?

Featured Maintenance, Repair & Overhaul Applications

3D scanning for Turbine Maintenance

Energetic Machinery in Belgium utilises GOM 3D scanners, photogrammetry and reverse engineering solutions in maintenance and repair applications of industrial turbine systems.

Reverse Engineering CNC Parts for Production

Using 3D scanning, we performed a CNC component redesign project by accurately creating a digital twin and reverse engineering for production. We used our latest scanning solution – the GOM Scan 1 – to perform this project.

Aerospace Restauration using 3D scanning

Raymond’s Aircraft Restoration restore, maintain and rebuild vintage aircraft. Get a glimpse of their passion and strong dedication to quality and precision – assisted by 3D scanning to reproduce missing parts.

Metal Forming Maintenance Workshop

Stahlotec is a maintenance workshop focused on sustainability, retrofitting and saving heavy components with mere millimetres of wear from being disposed of; a process that’s only possible with 3D metrology.