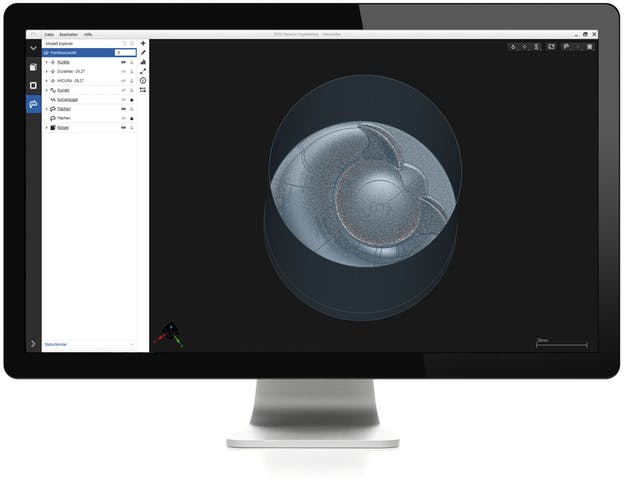

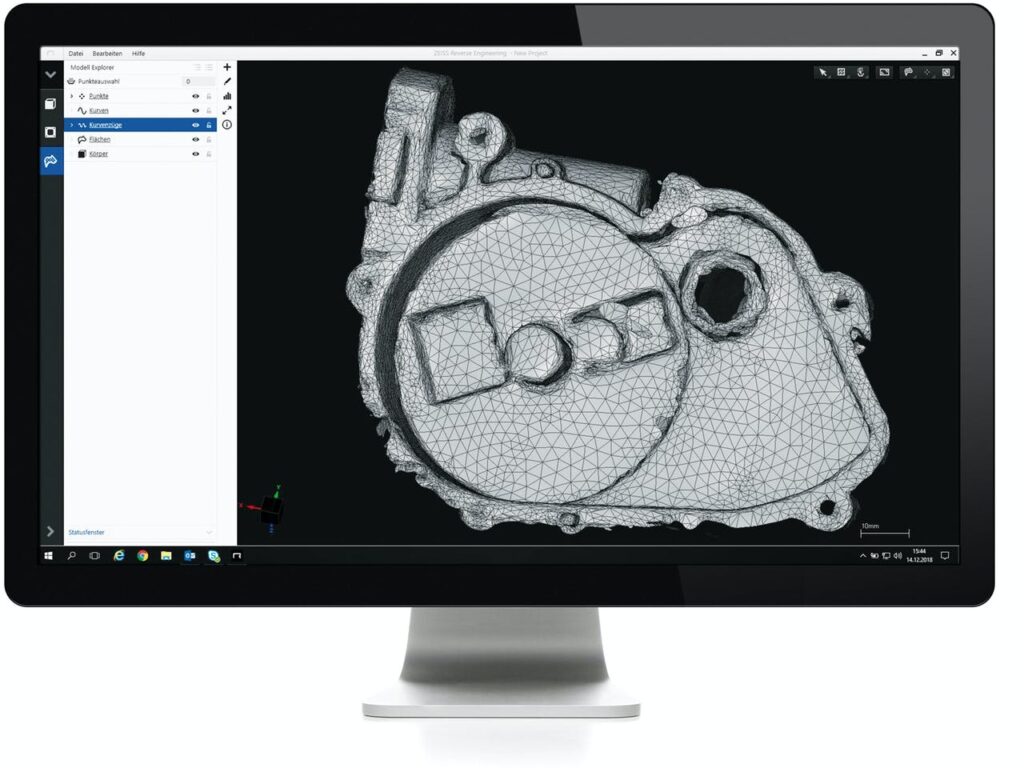

Zeiss Reverse Engineering Software

Import component scan data and recreate CAD model automatically using point clouds (al ASCII formats) or meshes (STL data). Export your model in a variety of formats for a variety of uses including; competitor analysis, recreating obsolete parts, and much more.

Zeiss Reverse Engineering allows you to save on iteration loops in the tool correction process leading to cost savings and quicker time to production. Use the software to simulate iterations and perform tooling corrections.

This functionality makes it possible to precisely determine crucial component volumes for applications in the fields of medical technology, automotive design, tool making and hydraulics. ZEISS REVERSE ENGINEERING volume makes this incredibly easy: the data captured is loaded to the VOLUME option, and then a mathematical algorithm is used to calculate an object’s volume. By automating numerous process steps you can eliminates potential operator errors, thereby ensuring precise, traceable measurement results.