The ARGUS system is integral to the analysis and optimisation of forming distributions of components. This system is predominantly tailored to the optimisation of sheet metal forming, with particular usefulness in the automotive industry. Examples of applications include deformation of parts during stamping, FEA comparison of formed parts and forming limit analysis for tool optimisation.

The measurement sensor provides the following information:

- 3D Measurement Co-Ordinates of Part Surface

- Form Change Range (Minor & Major Strain)

- Thickness Changes

- Forming Limit Diagram (FLD)

Technical Features

Verification of Finite Element Simulation

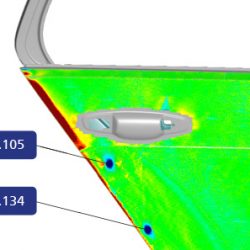

Alongside numerical simulations, optical metrology systems have significantly aided the quality of forming, while also reducing production times through increased efficiency. ARGUS strongly supports the verification of Finite Element Simulations. The accompanying software allows the import of FE datasets in order to compare the full-field numerical forming data for sheet metal parts.

Optimization of the Forming Process

The ARGUS system is integral to the analysis and optimisation of forming distributions of components. This system is predominantly tailored to the optimisation of sheet metal forming, with particular usefulness in the automotive industry. Information such as thickness change, form change range and forming limit diagrams can be generated by the ARGUS solution.

Cutting Edge Software

The optical system works with a sophisticated software to generate forming limit diagrams and curves to calculate areas of critical forming. Further deformation analysis is possible with the wide range of functionality available for user needs