ZEISS CMM

ZEISS Coordinate Measurement Machines (CMMs) offer best-in-class precision, accuracy and repeatability in industrial metrology for quality inspection applications.

ZEISS VMM

ZEISS Vision & Multi-Sensor Machines (O-Detect & O-Inspect) help measure small to medium sized components for various applications.

GOM Touch Probe

The touch probe is a metrology add on to the ATOS optical measurement systems that provides precise 3D co-ordinate points for difficult to access areas, hidden cavities and discreet points.

Featured CMM & Vision Measurement Applications

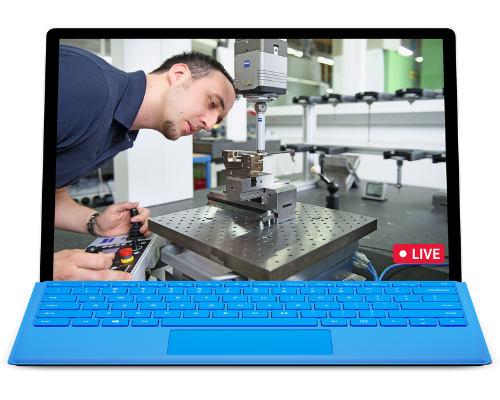

Australian ZEISS CMM Webinar

This webinar provides you with a better understanding of how ZEISS CMMs should be integrated into each process to ensure a high product quality while maintaining efficiency throughput while eliminating waste and rework.

ZEISS CONTURA CMM for Aerospace Applications

Michigan Scientific, purchased their first ZEISS CMM for a new aerospace contract, requiring high precision and GD&T drawing measurements.

ZEISS CONTURA CMM for Medical Device Inspection

Schupan, located in Kalamazoo, Michigan, specializes in metals & plastics — distribution stock, precision cutting, custom extrusions, and manufacturing services.