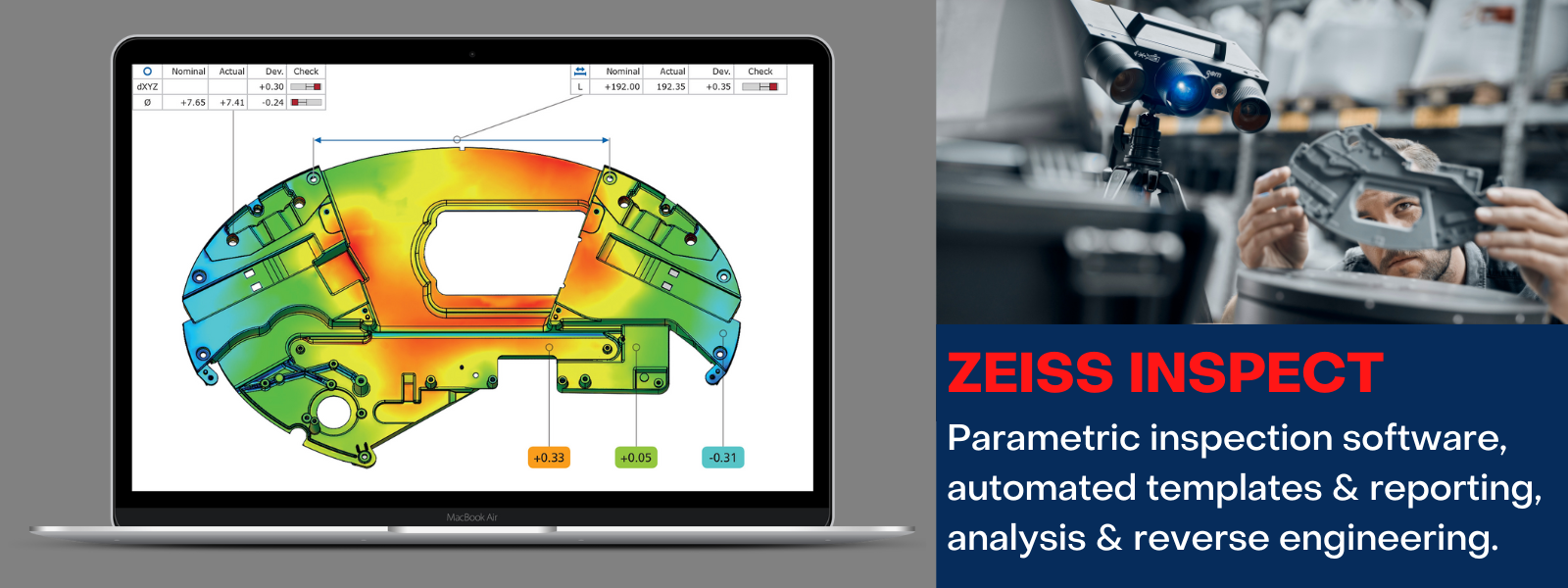

ZEISS INSPECT is a comprehensive software package featuring four distinct modules enabling you to capture 3D scan data, perform inspection and GD&T, CAD comparison and reverse engineering. The software packages comes by default with ZEISS 3D scanning systems and ZEISS CT & X-Ray machines.

ZEISS INSPECT Variants

ZEISS INSPECT Optical 3D

Capture 3D data and perform inspection, CAD comparison, and GD&T with speed. ZEISS INSPECT also features advanced manufacturing and automation functionalities such as automated inspection templates, trend analyses, digital assembly or proprietary inspection.

ZEISS INSPECT Correlate

Digital image correlation (DIC) and evaluation software for materials research and component testing. Pair with ARAMIS 3D camera system to evaluate surface motion and deformation. Using a stochastic pattern or point markers, images areas can be described with sub-pixel accuracy.

Featured Applications

Using the GOM Scan 1, we performed a 3D scan of a classic Ford Falcon hood scoop. We reverse engineered and modified its geometry and length to allow our client to add some power to his engine.

Using the GOM Scan 1, AESUB and Delta WASP 3D printers; we scanned, reverse engineered and manufactured a complex object, showcasing how 3D scanning and 3D printing can be used to solve design and manufacturing problems.