20 Jul Amiga Engineering – ATOS Q for Manufacturing Quality Control

Scan-Xpress performed an Aerospace quality control project for Australian partners Amiga Engineering and Silvertone UAV. Following this project, Amiga Engineering became interested in the ATOS Q sensors for quality control applications as part of its additive manufacturing production line due to the critical feedback it was able to provide during this project.

Read full project details here >

Selecting the right metrology tool

Amiga Engineering was looking to improve its quality control capabilities having recently found their CMM system unable to perform certain critical operations. Optical 3D scanning offered an interesting and complementary alternative part inspection and analysis applications.

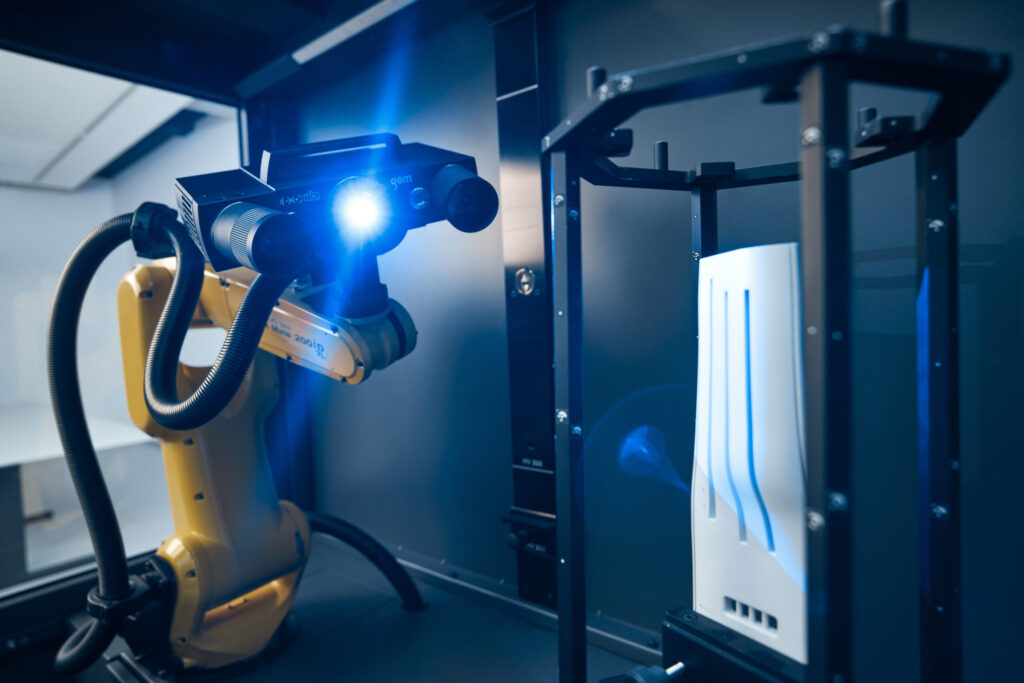

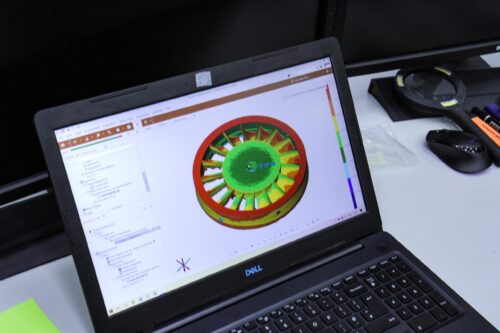

Optical scanning is much faster than a CMM while also providing full-field part data instead of localised point data. This allows you to perform CAD comparisons and analyses based on complete surface data providing much more data and insight. The ATOS Q sensor which had only just been launched in 2019 provided industrial level precision at an attractive price point and was purchased by Amiga to complement and, for certain projects, replace their existing touch-metrology system.

ATOS Q at Amiga Engineering

In the video above provided by Amiga Engineering, you can see why 3D optical metrology and the ATOS Q were selected for the manufacturers application. The video highlights its uses and how it pairs perfectly as a quality control solution for additive and precision manufacturing processes.

Benefits of 3D Scanning

As we can see from the video above, the ATOS Q 3D scanner provides a versatile solution for quality control of complex geometry parts. It enables an operator to obtain complete 3D scan data quickly, with minimal part manipulation and no CMM programming required. This is especially useful in applications where different parts are produced in low quantities but still require accurate quality checks to be performed.

Furthermore, optical metrology has recently reached accuracy and automation levels previously only available with high-end CMMs. As our partners at Amiga mentioned, the ATOS Q a powerful and precise tool made for industrial-level quality control. However, its functionality and interface make it easy to use and does not require extensive training or set-up to become operational.

Finally, one of the greatest advantages of optical metrology is its ability to provide full-field data. The whole part is accurately mapped and modelled virtually, instead of simple point based measurements as would be the case with traditional CMMs. Having access to this data allows manufacturers to perform CAD comparisons allowing for effective design and tool correction iterations. This also enables operators to reverse engineer parts with ease and accuracy.

If you would like to know more about the potential of 3D scanners and how they would be suited for your production line, feel free to contact us >

Interested in reading about our next projects and company news?