23 Aug Webinar: GOM Suite 2021 Update eLearning

Scan-Xpress invited its customers and software users to an exclusive webinar exploring new functionalities of the latest software update. During this LIVE-Online event Benjamin Singer (Metrology Expert) and Josh Span (Quality Control Application Engineer) discussed the latest features and updates to GOM Suite 2021.GOM Suite 2021 eLearning Recording

Here is a recording of the LIVE eLearning event that took place on Thursday September 2nd 2021.Showcased 3D inspection tools

During the eLearning recording, you may have noticed our team used the ATOS Q and ROT 350 automatic rotation table for the demonstration. The ATOS Q is a 3D scanner offering industrial level precision for quality control and 3D inspection. It easily competes with most CMMs in tolerance checks and GD&T while offering all the benefits and speed advantages of optical metrology.

The ATOS Q is a 3D scanner offering industrial level precision for quality control and 3D inspection. It easily competes with most CMMs in tolerance checks and GD&T while offering all the benefits and speed advantages of optical metrology.

The ROT 350 is an automatic rotation table enabling entry-level automation for small to medium sized parts. It can be combined with any 3D scanner and meshes perfectly with GOM Suite 2021 enabling a streamlined workflow saving you time and resources.

The ROT 350 is an automatic rotation table enabling entry-level automation for small to medium sized parts. It can be combined with any 3D scanner and meshes perfectly with GOM Suite 2021 enabling a streamlined workflow saving you time and resources.

Presentation Highlights

As we can see in the recording, there have been many improvements to the software with updates including user interface simplification, a new, simple workflow assistant as well as awesome 3D inspection features.Highlight #1: New User Interface

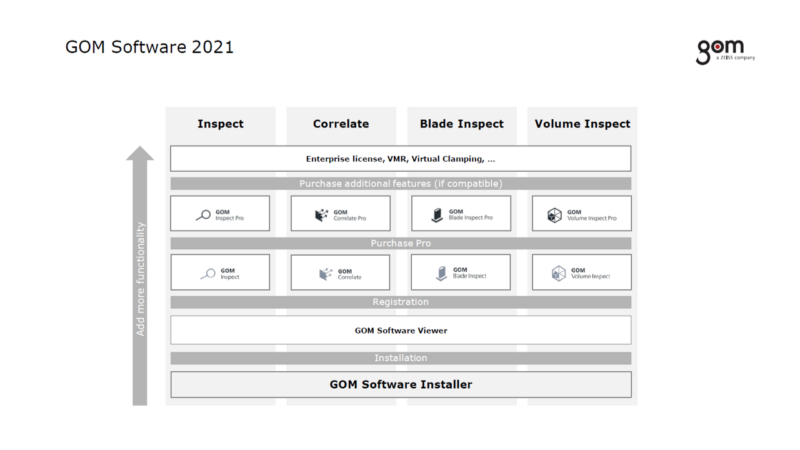

The latest update to the software includes a centralisation of all the features and applications into one single package. This will make it easier to jump from one inspection package to another as well as add new functionalities.

Highlight #2: Workflow assistant

This new feature guides you through the inspection process every step of the way. With automatic prompts and tips to ensure you get the best data possible, this is a great feature that will save you time and minimize training for new users. Check out the video by GOM below for a quick preview and tutorial.Highlight #3: Quick GD&T

Geometric Dimensioning and Tolerancing (GD&T) is the basis of all 3D inspection and quality control. The new software interface allows you to inspect virtually any feature at the click of a button. Check out the full tutorial by GOM in the video below:Highlight #4: Multipart Scanning

This is an amazing new feature enabling you to scan multiple parts at the same time within the same project. Use this to simplify your workflow and improve efficiency.Highlight #5: Temperature Compensation

When measuring on site or on the shop floor, your environment may not be as controlled as you would like it. Using this feature, you can virtually scale the measured data to match your nominal measurement temperature. This will allow you to perform reliable CAD comparisons in any setting.

Interested in reading about our next projects and company news?

Subscribe