With GOM Inspect Professional inspection becomes faster and easier. GOM Inspect Professional offers all features of GOM Inspect plus additional user benefits – all to increase the efficiency of your workflow.

Professional Features

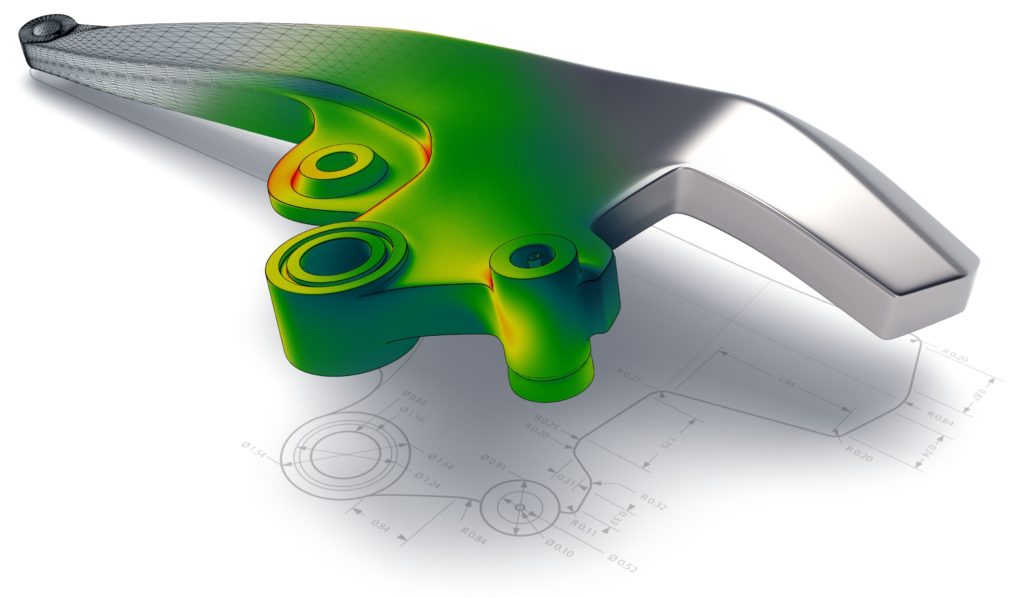

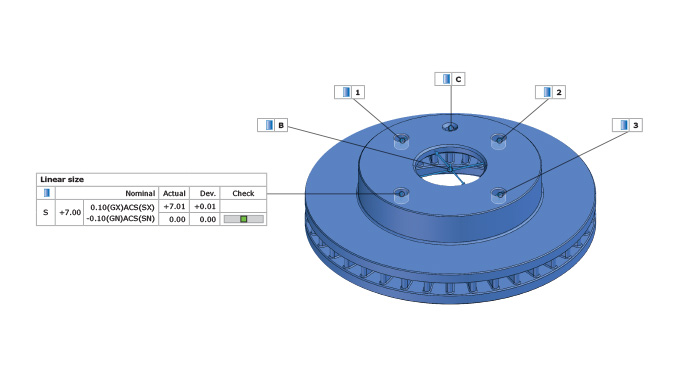

Parametric Inspection

The GOM software is based on a parametric concept, which forms the underlying foundation for every function. This parametric approach ensures that all process steps are traceable, thus guaranteeing process reliability for measuring results and reports.

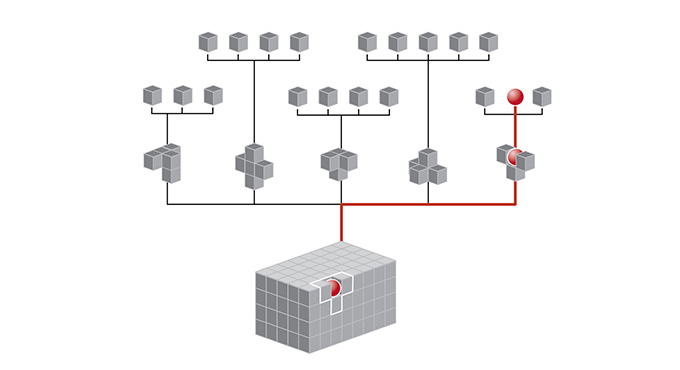

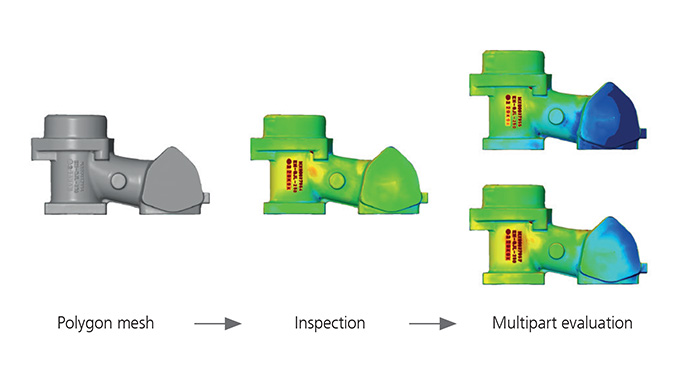

Teaching By Doing

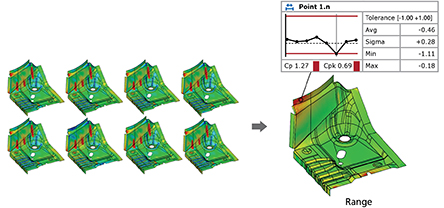

With Teaching by Doing, any completed evaluation can be easily applied to two or more parts. Thanks to the parametric design, the software automatically stores each individual inspection step. There is no difference between single and multiple evaluations. All evaluation steps can be operated without scripting, previous planning or user intervention, so that no time is spent on programming.

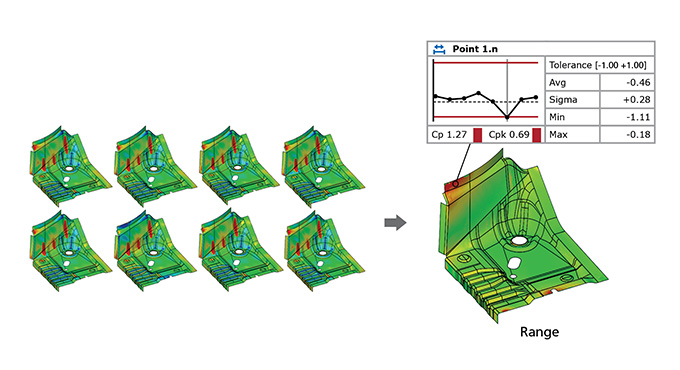

Part Trend Analysis

The underlying parametric concept of the GOM software enables a trend analysis for multiple evaluations, for example, in statistical process control (SPC) or for deformation analysis. This enables full-field evaluation of several parts or stages within a single project and offers functionalities for determining statistical analysis values such as Cp, Cpk, Pp, Ppk, Min, Max, Avg and Sigma.

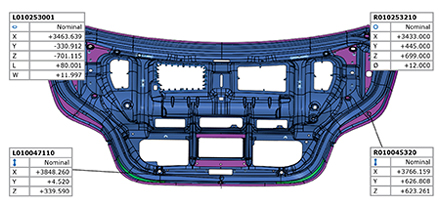

CAD/Measurement Plan Import

GOM Inspect allows for CAD file imports from a range of different formats, including JT Open, STEP, IGES, CATIA & Solidworks files. Measurement plans can also be taken in by the software in formats of CSV, DMI, ASCII, IPP and FTA to work as the basis of inspection. The simplicity of GOM Inspect allows for a drag and drop of CAD files into the software, in which are automatically identified and assigned by the software.

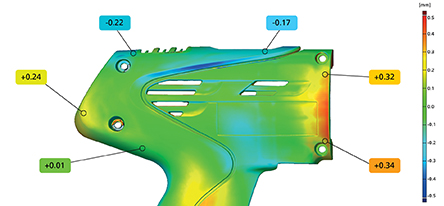

CAD Comparison

Polygon meshes can be aligned and compared to CAD data or technical drawings. This allows for an analysis of part surfaces, as well as 2D inspection such as sections, planes, lines and circles. The surface comparison heat map is the standard inspection function when searching for part defects.

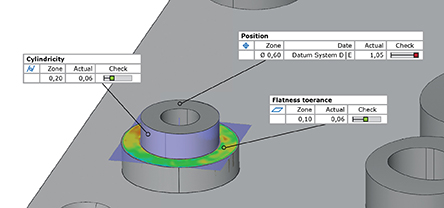

GD&T Analysis

The software conducts GD&T analysis in conformance with ASME and ISO standards. Functionality such as parallelism, cylindricity, flatness, two-point distances, position tolerance and thickness are all possible within GOM Inspect.

Trend and Deformation Analysis

The GOM software is inbuilt with trend functionality that makes evaluation of multiple parts or stages possible within a single project. Statistical Process Control (SPC) is supported, with values of Cp, Cpk, Pp, Ppk, Min, Max, Avg & Sigma contained within GOM Inspect.

Inspection Plan Import

GOM supports interfaces for digital transfers of inspection features to assist PLM (Product Lifecycle Management) and PMI (Product Manufacturing Information). Quality criteria and datum systems that were implemented by a semantic construction into the CAD can be transferred digitally and evaluated in a context-sensitive way. Since the inspection plan is generated directly during the CAD import, additional work-intensive programming is not necessary.

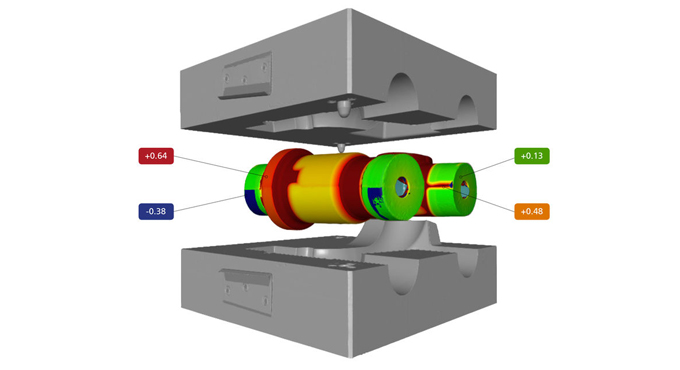

Digital Assembly – Projects with Multiple Parts

In digital assembly, several components can be virtually aligned to each other. The inspection is based on parts. This feature increases the flexibility, e.g. for the alignment of components as well as for the analysis of gap and flush or material thickness.

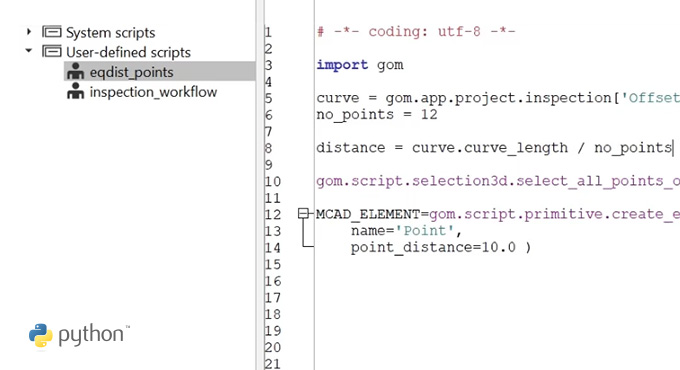

Scripting

The concept of scripting bases on a command recorder, which can record all executed operations in the software. The software saves the recording as Python script. That way, you can execute the recording repeatedly. By editing the recorded script, you can adapt the script to other tasks or generalize it. The programming is based on modification or combination of recordings.

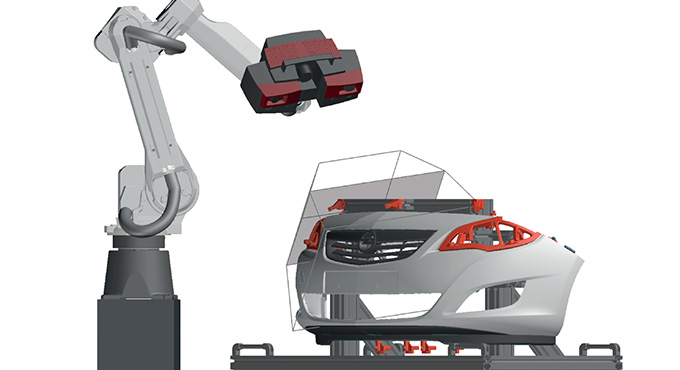

Virtual Measuring Room

The VMR is a virtual, yet functional representation of the real world. The VMR is a fully integrated solution, allowing for the complete reproduction of automated measurement processes. Combining the parametric inspection processes offered by GOM Inspect Professional, the VMR enables the execution of automated measurements: import of measurement plans, offline and online programming, 3D measurement simulation, collision control, safety, data capturing, inspection and reporting.

GOM Inspect & GOM Inspect Professional Comparison

Inspection Features

GOM Inspect

GOM Inspect Professional

GOM Inspect Enterprise

Polygonize Point Cloud Data

Polygonize Point Cloud Data

Polygonize Point Cloud Data

Polygonize Point Cloud Data

Import/Export Measuring Data (ASCII, STL, PSL, PLY, CT Data)

Import/Export Measuring Data (ASCII, STL, PSL, PLY, CT Data)

Import/Export Measuring Data (ASCII, STL, PSL, PLY, CT Data)

Import/Export Measuring Data (ASCII, STL, PSL, PLY, CT Data)

CAD Import Basis (IGES, STP, PLY...)

CAD Import Basis (IGES, STP, PLY...)

CAD Import Basis (IGES, STP, PLY...)

CAD Import Basis (IGES, STP, PLY...)

Mesh Processing (Laser Scanners, CTs, White Light Scanners)

Mesh Processing (Laser Scanners, CTs, White Light Scanners)

Mesh Processing (Laser Scanners, CTs, White Light Scanners)

Mesh Processing (Laser Scanners, CTs, White Light Scanners)

Alignments and Local Coordinate Systems

Alignments and Local Coordinate Systems

Alignments and Local Coordinate Systems

Alignments and Local Coordinate Systems

Nominal/Actual Comparison

Nominal/Actual Comparison

Nominal/Actual Comparison

Nominal/Actual Comparison

Geometric Dimension and Tolerancing (GD&T)

Geometric Dimension and Tolerancing (GD&T)

Geometric Dimension and Tolerancing (GD&T)

Geometric Dimension and Tolerancing (GD&T)

Curve Inspection

Curve Inspection

Curve Inspection

Curve Inspection

Airfoil Inspection

Airfoil Inspection

Airfoil Inspection

Airfoil Inspection

Surface Defect Inspection

Surface Defect Inspection

Surface Defect Inspection

Surface Defect Inspection

Reporting

Reporting

Reporting

Reporting

Traceability

Traceability

Traceability

Traceability

Parametric Inspection

Parametric Inspection

Parametric Inspection

Parametric Inspection

Teaching by Doing

Teaching by Doing

Teaching by Doing

Teaching by Doing

Part Trend Analysis

Part Trend Analysis

Part Trend Analysis

Part Trend Analysis

CAD Import Native (CATIA, UG, Pro/E, ...)

CAD Import Native (CATIA, UG, Pro/E, ...)

CAD Import Native (CATIA, UG, Pro/E, ...)

CAD Import Native (CATIA, UG, Pro/E, ...)

CAD Import with Semantic PMI/FTA/MBD

CAD Import with Semantic PMI/FTA/MBD

CAD Import with Semantic PMI/FTA/MBD

CAD Import with Semantic PMI/FTA/MBD

Customisation with Project Templates

Customisation with Project Templates

Customisation with Project Templates

Customisation with Project Templates

Digital Assembly: Add a New Part

Digital Assembly: Add a New Part

Digital Assembly: Add a New Part

Digital Assembly: Add a New Part

Scripting

Scripting

Scripting

Scripting

Virtual Measuring Room (Additional Module)

Virtual Measuring Room (Additional Module)

Virtual Measuring Room (Additional Module)

Virtual Measuring Room (Additional Module)

Virtual Clamping (Additional Module)

Virtual Clamping (Additional Module)

Virtual Clamping (Additional Module)

Virtual Clamping (Additional Module)

Flexible Solution for Network License

Flexible Solution for Network License

Flexible Solution for Network License

Flexible Solution for Network License