31 Oct Surface Treatment for 3D Scanning

This article provides a background on surface treatment for 3D Scanning and investigates the layer thickness of several commercially available surface treatments.Why do we need to treat surfaces for 3D scanning?

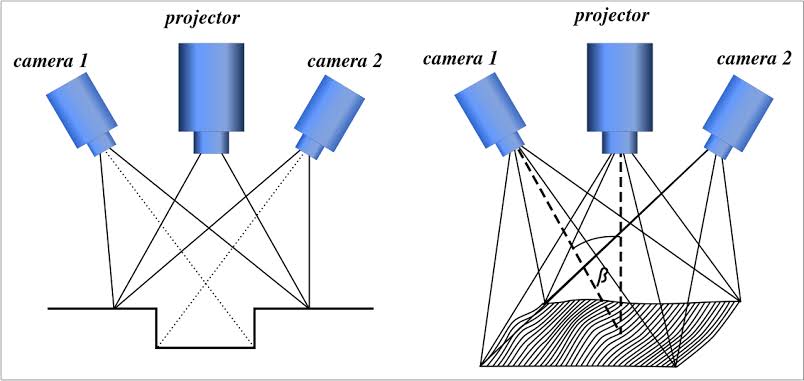

Even with state of the art 3D scanners, there are going to be certain applications that require surface treatment. This is because 3D Scanners are optical based – they project either structured light or lasers on a surface and the cameras determine geometry based upon the projected light pattern. The main types of surfaces that require treatment are dark, transparent and shiny or reflective surfaces. Dark surfaces absorb the projected light which prevents the cameras from inferring geometry. On transparent parts, the light projects through the surface and the cameras cannot ‘see’ the surface. With shiny and reflective parts, the projected light scatters on the surface and the cameras cannot determine meaningful surface information. An ideal surface for 3D Scanning is an opaque, matte white surface.

The main types of surfaces that require treatment are dark, transparent and shiny or reflective surfaces. Dark surfaces absorb the projected light which prevents the cameras from inferring geometry. On transparent parts, the light projects through the surface and the cameras cannot ‘see’ the surface. With shiny and reflective parts, the projected light scatters on the surface and the cameras cannot determine meaningful surface information. An ideal surface for 3D Scanning is an opaque, matte white surface.

What are the options for surface treatment?

There are many surface treatment options available. We have investigated the following dedicated surface treatment options:AESUB Blue

This is the latest state of the art disappearing 3D Scanning Spray. Because it disappears you do not need to clean it after use. It has been developed by and for the 3D Scanning Industry. It provides a very homogeneous layer.

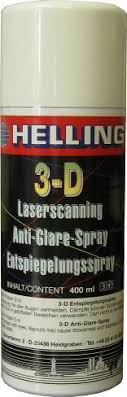

Helling 3D Laser Scanning Spray

This is a regular non-vanishing scanning spray and requires cleaning after use. The spray can be wiped or brushed off. When there are deep pockets on your specimen you will not be able to clean it perfectly. It provides a homogeneous layer.

MR 2000 Anti-Reflex L

This is also a regular non-vanishing scanning spray and requires cleaning after use. It felt like there was a lot of pressure in the can during application. It provides a homogeneous layer similar to the Helling Spray.

MR 1000 Anti-Reflex W

This is a waterbased mixture that can be applied using a high-quality airbrush gun. The surface applied can be a bit grainy which is problematic if you require high-resolution scan data. It can be removed using water and a cloth.

Scholz KRONOS 2300

This treatment is a powder which is combined with an isopropanol solution and applied with a high-quality airbrush gun. The powder contains titanium dioxide which is a known carcinogen. It needs to be removed after scanning. It is easy to remove from metal parts but it cannot be cleaned from most plastic parts.

Reflecon Tarnish-11-HC

This is a similar spray to AESUB blue because it disappears after use. The surface was a bit grainier and not as homogeneous compared to AESUB blue.

Kremer Pigmente Cyclododecane Spray

This is the ‘old’ vanishing spray which is replaced by AESUB. The surface is very uneven and has a snow-flake effect that causes lots of small peaks and bumps. Especially when you are using a high-end scanner you will see all these artefacts in the scan result.

How thick is a layer of spray from each surface treatment?

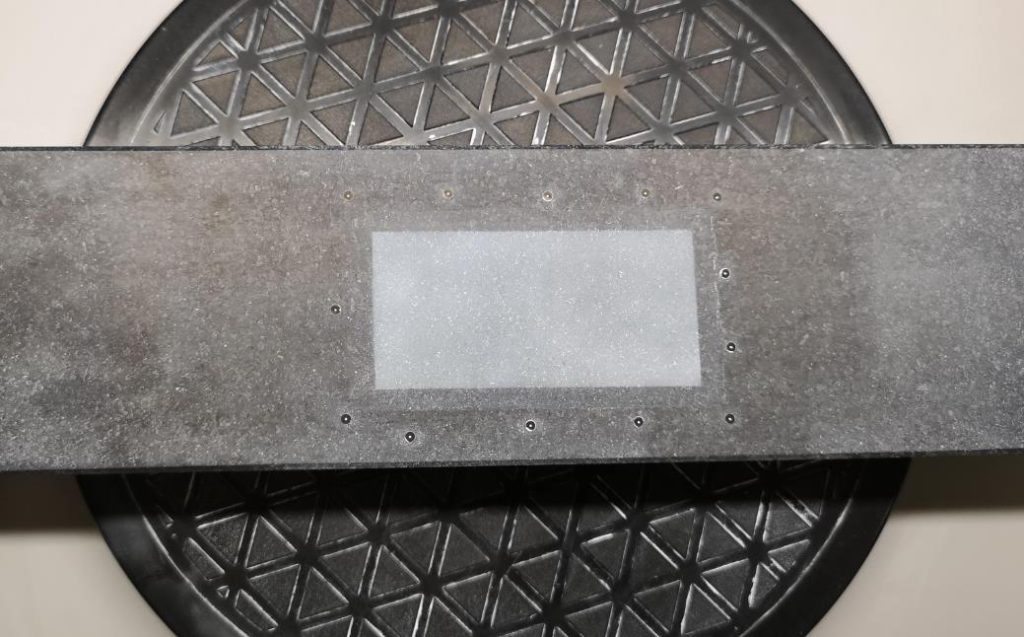

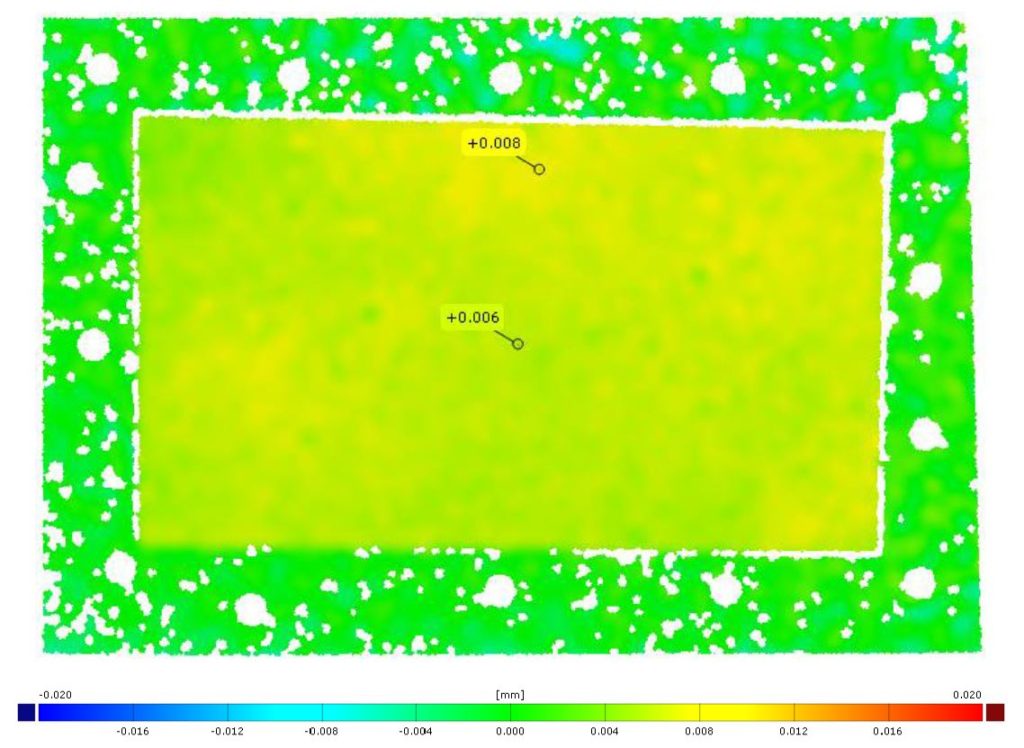

To investigate the layer thicknesses we used an ATOS III Triple Scan with a 100mm Measurement Volume. A ceramic flatness artefact is used as a reference substrate to provide an ideal flat reference plane. Prior to application of the spray, the ceramic plate was covered with tape and reference markers. A rectangular area was left open for application of the spray. Once the spray was applied, the tape was removed and the artefact was measured on a rotation plate using several scans. The layer thickness was determined by using the ceramic flatness plate as a reference. An example of the results is given below.

Prior to application of the spray, the ceramic plate was covered with tape and reference markers. A rectangular area was left open for application of the spray. Once the spray was applied, the tape was removed and the artefact was measured on a rotation plate using several scans. The layer thickness was determined by using the ceramic flatness plate as a reference. An example of the results is given below.

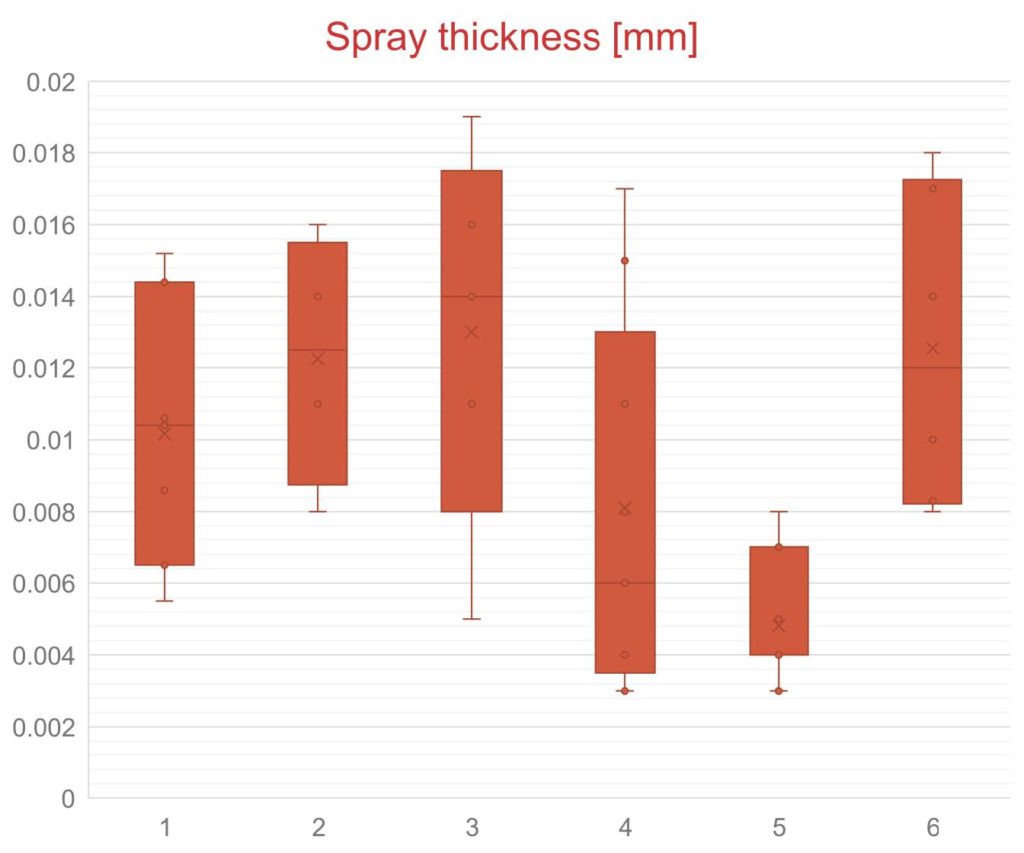

The average, maximum and minimum deviations from the background plate were determined. The full results are displayed on the box plot below.

The surface treatments in the graph below are:

1. AESUB Blue

2. Helling 3D Laser Scanning Spray

3. MR 2000 Anti-Reflex L

4. MR 1000 Anti-Reflex W

5. Scholz Kronos 2300

6. Reflecon Tarnish-11-HC

Kremer Pigments Cyclododecane Spray (not in graph) had an average layer thickness of 0.054mm

The average, maximum and minimum deviations from the background plate were determined. The full results are displayed on the box plot below.

The surface treatments in the graph below are:

1. AESUB Blue

2. Helling 3D Laser Scanning Spray

3. MR 2000 Anti-Reflex L

4. MR 1000 Anti-Reflex W

5. Scholz Kronos 2300

6. Reflecon Tarnish-11-HC

Kremer Pigments Cyclododecane Spray (not in graph) had an average layer thickness of 0.054mm

You can purchase AESUB Blue from Scan-Xpress here

This Investigation was performed by TetraVision BVBA. Download the white paper here

You can purchase AESUB Blue from Scan-Xpress here

This Investigation was performed by TetraVision BVBA. Download the white paper here