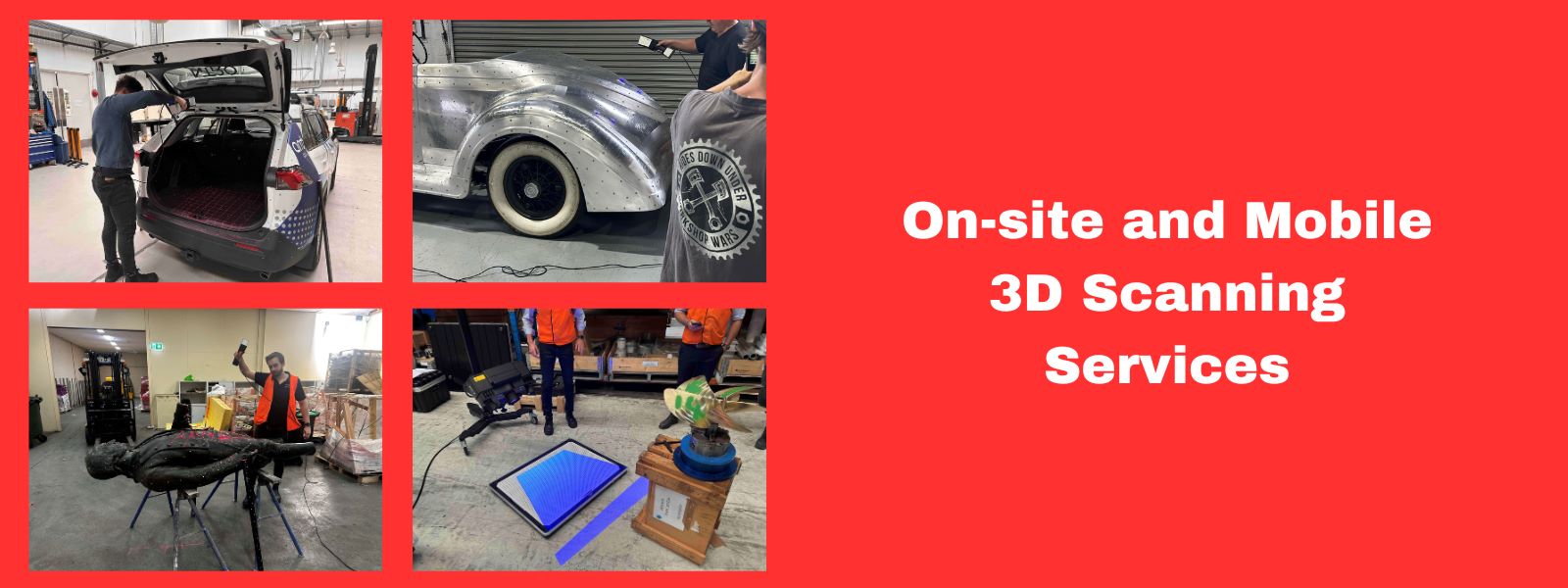

With offices located in both Melbourne, VIC and Sydney, NSW; Scan-Xpress provide cost effective, high-precision 3D scanning (including laser and terrestrial), measurement, inspection and reverse-engineering services. Using our dedicated Metrology systems – we service any location across Australia, New Zealand and further afield if required. Our team are committed to supporting you by providing either a mobile or on-site, tailored service offering to enable you to meet your objectives.

Applications

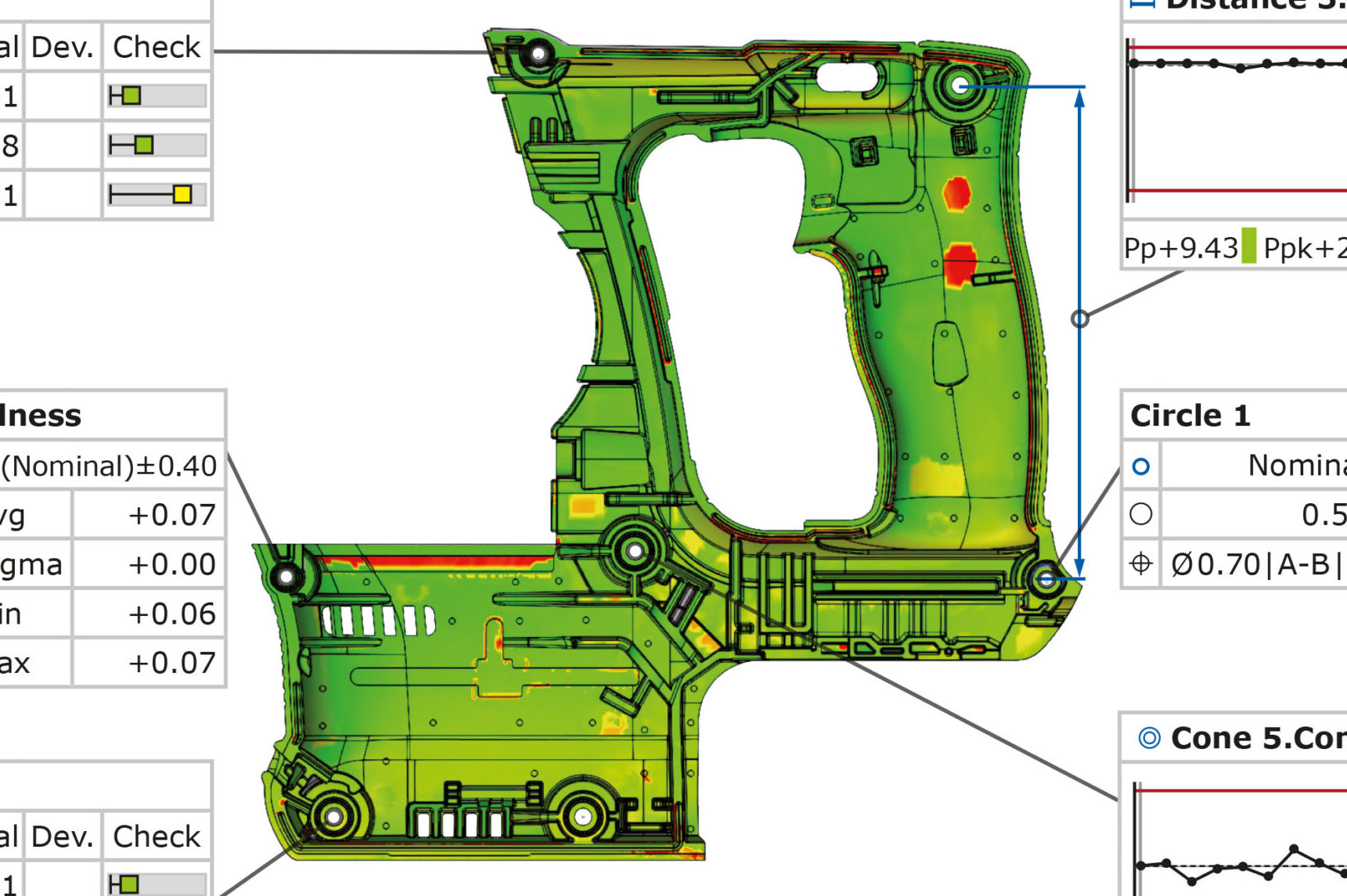

Quality Control & Inspection

3D scanning plays a crucial role in quality control and inspection by enabling precise, non-contact measurement of manufactured parts. By comparing the scanned 3D model of a physical object to its original CAD design, engineers can quickly identify deviations, defects, or dimensional inaccuracies.

Reverse Engineering

3D scanning is widely used in reverse engineering to capture the exact geometry of existing physical objects and convert them into digital 3D models. This allows engineers to analyse, modify, or recreate parts — especially when original design files are missing or outdated, making it invaluable for legacy equipment, custom components, or competitive analysis.

Mobile 3D scanning process

Send us your part

We discuss your project requirements

One of our experienced team members performs a 3D scan

Our team processes the scan & sends your data

Dedicated Measurement & Inspection Tools

At Scan-Xpress, we offer cutting-edge measurement and inspection solutions to deliver you high precision data for your part size and needs. Browse through our most popular systems below.

The ZEISS ScanBox Series 5 is an all-in-one solution for automated inspection and digitisation of complex parts and offers many options for adapting to your needs. The maximum load of the rotation table module is 2,000 kg.

The ZEISS T-SCAN Hawk 2‘s portability and reliability allow capture of data with metrology-grade precision wherever needed. Objects of multiple metres in size can be scanned without compromising on accuracy.

The GOM Scan 1 is a 3D scanner, equipped with fringe projection and blue light technology which enables precise mesh capture of 6 million points per scan. Main areas of application include quality control, reverse engineering and additive manufacturing.

Our Laser Tracker services are designed to enable your organisation to build, inspect and measure products and parts quickly, simply and precisely. Built on micron-level accuracy, the system will increase throughput while maintaining high inspection accuracy.

Equipped with intuitive hardware and versatile software offerings – our mobile Terrestrial Laser Scanner is a comprehensive services solution for capturing precise 3D digital models, faster data sharing, and on-site efficiency.

Book a Discovery Call with us Today!