07 May 3D Scan & Reverse Engineering of Medical Screws

Customer: MAXONIQ

Objective: 3D Scan & Reverse Engineering of small medical devices

MAXONIQ, a company specialising in the design and manufacture of medical devices and surgical implants, contracted Scan-Xpress to 3D scan and reverse engineer a series of small surgical screws. These screws are used in surgical applications for fixing and clamping custom-made inserts to human tissue, such as bones, as shown in the image below.

The torsional moment or rotational force that is created during the screwing process generates a tensile stress along the length of the screw and it is this stress that ensures the insert remains in place.

In order to accurately determine the effectiveness of these screws and fine tune their design, MAXONIQ required the creation of an accurate 3D CAD model based on the prototype screw which would enable them to perform Finite Element Analyses (FEA) in a digitally simulated environment.

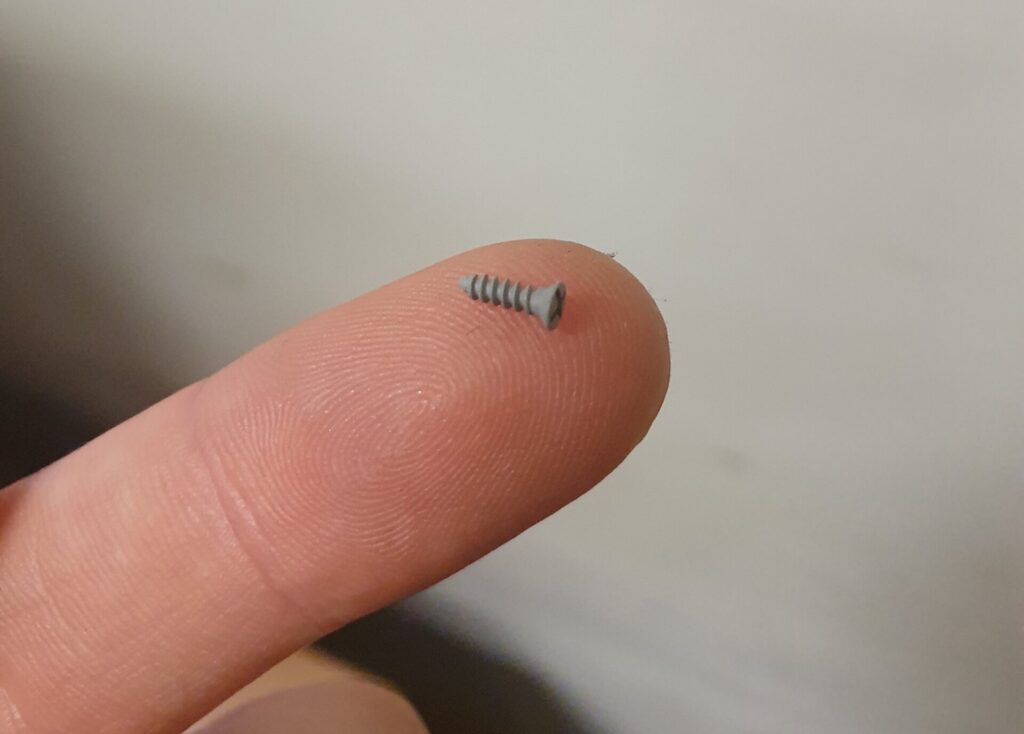

The screws varied between 1.5mm and 3mm in diameter and required a system capable of high resolution scanning of small object volumes. The ATOS Compact Scan with a 45mm measurement volume was selected for this application due to its 17 micron resolution. Image below show Compact Scan and its field of view scan image of the screw and reference markers used during scan process.

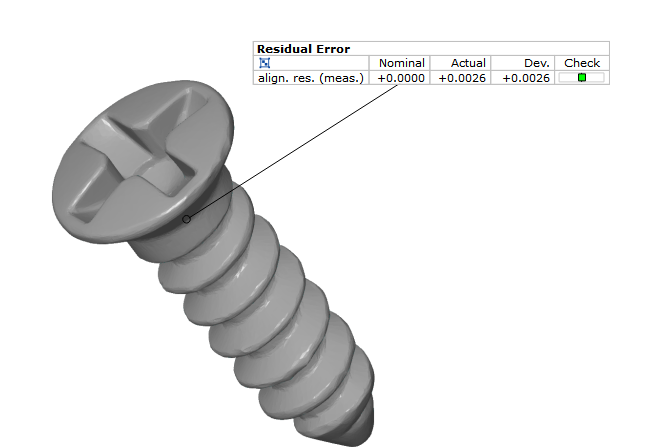

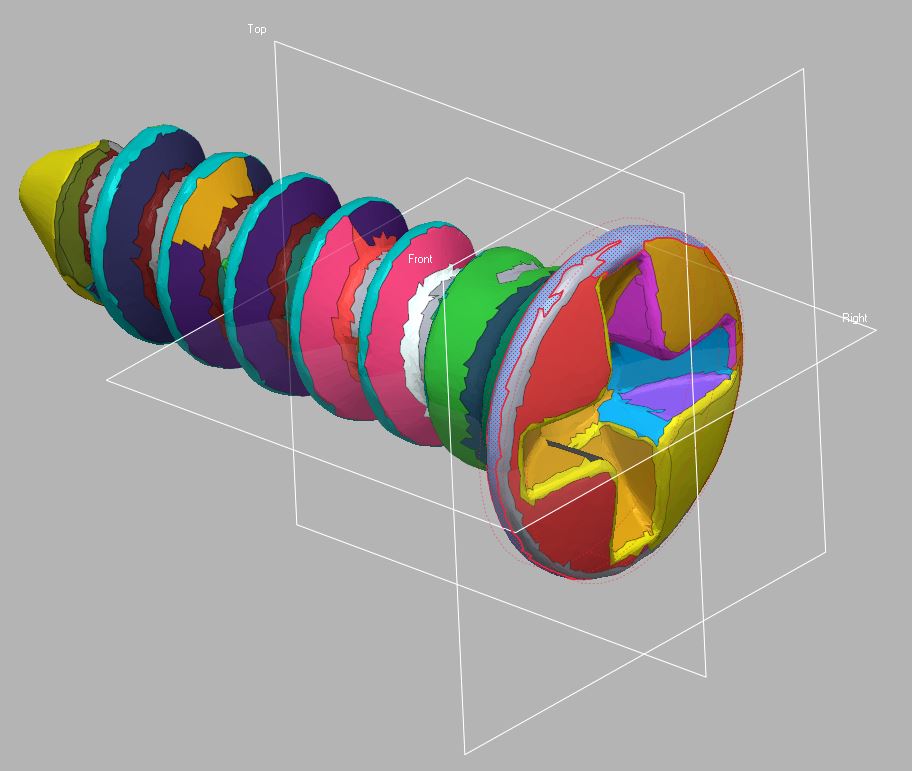

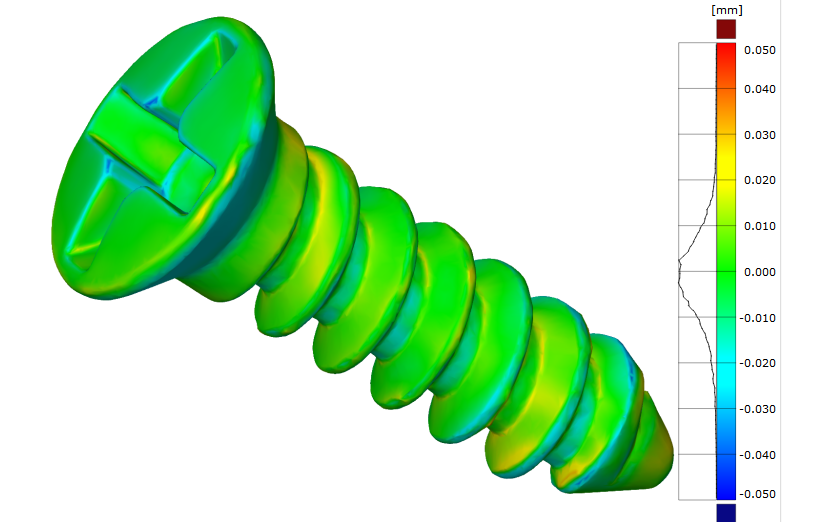

The resulting scan provided a 2.6 micron residual error enabling our team to create a highly accurate full-field 3D model. We then used Geomagic Design X reverse engineering software to subdivide the scan into geometric regions. The images bellow show the final scan data residual error (left) as well as the Geomagic Design X identified geometry (right).

Geomagic Design X then uses the regions to estimate surface geometries and create a 3D CAD model from the scan data (left image below). This CAD model is a best-fit representation of the original scan and can then be used in in digital assembly and testing environments (right image below – surface deviation analysis between CAD and Scan Data).

The resulting model enabled our customer to perform FEA analyses and accurately determine the stresses exerted by and on the surgical screw during proceedure in order to fine-tune their design.

Interested in reading about our next projects and company news?