We are committed to working with you to understand your quality control, reverse engineering, 3D measurement, scanning and inspection requirements for a wide variety of applications. Once we establish what your specific requirements are, we tailor our service offering to enable you to meet your objectives.

Where our 3D industrial metrology systems make an impact

AUTOMOTIVE

Provides precise, reliable measurements that ensure high-quality manufacturing and streamline production processes.

AEROSPACE

Accurate measurement and alignment of aircraft components and structures to meet strict industry standards.

MEDICAL

Delivers precise measurements that enhance the design, production, and quality control of medical devices and implants.

RAIL & TRANSPORTATION

Inspection and verification of tooling, fixtures, and assembled vehicles or components.

POWER GENERATION

Provides accurate measurements for the inspection and maintenance of critical components, ensuring optimal performance, reliability, and extended lifespan.

MINING

Enables precise measurement and inspection of equipment and parts, improving operational efficiency, reducing downtime, and ensuring safety and durability.

Your unique measurement challenges.

Our precision solutions.

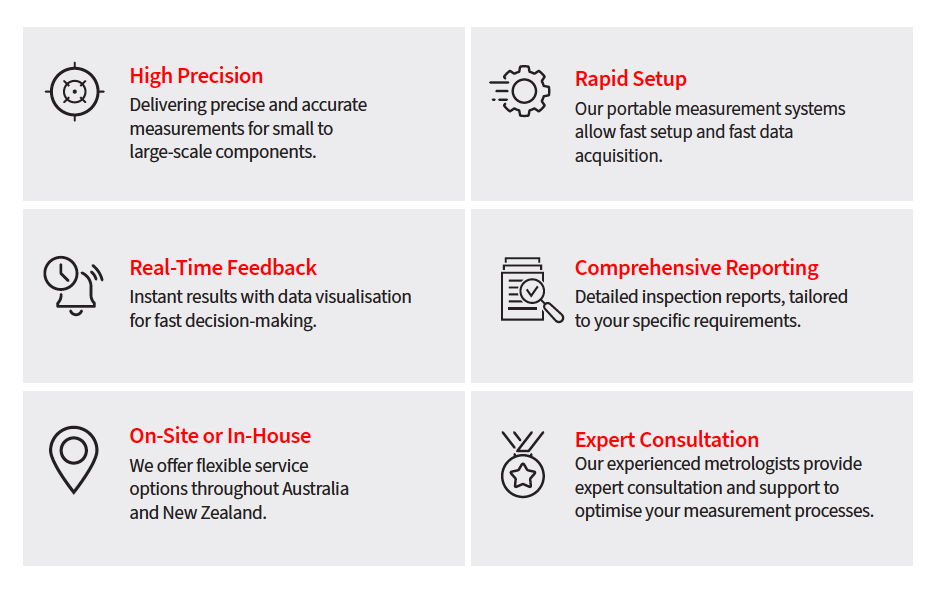

We provide high-precision 3D scanning services using our dedicated Metrology systems at any location across Australia, New Zealand, and further afield, if required. Here’s how we deliver exceptional results:

Why Scan-Xpress is YOUR Partner in Innovation

When precision matters, experience counts.

At Scan-Xpress, we bring 28 years of expertise in 3D metrology, using industry-leading Metrology Systems to deliver high-accuracy measurement solutions you can trust. Here’s why leading industries rely on us:

Expertise and Experience:

With three decades of experience, our skilled team brings extensive knowledge in 3D metrology ensuring that every project is executed with precision and attention to detail.

Fast Turnaround:

We deliver accurate and timely inspection results, helping you keep your projects on schedule.

Customised Solutions:

Every project is unique. We tailor our services to meet the specific needs and standards of your industry.

Proven Track Record:

We have successfully worked with clients across industries such as aerospace, automotive, energy, shipbuilding, heavy engineering and more.

Success Stories

Automotive 3D Scanning & Reverse Engineering

Using the GOM Scan 1, we performed a 3D scan of a classic Ford Falcon hood scoop. We reverse engineered and modified its geometry and length to allow our client to add some power to his engine.

Marine 3D Scanning & Quality Inspection

One of our prospective customers was looking to use 3D scanning for quality control and reverse engineering of marine propellers. We used the ATOS Q to capture full field 3D data, enabling us to compare to CAD and identify critical defects.