21 Oct Marine Propeller Quality Control

Project Details

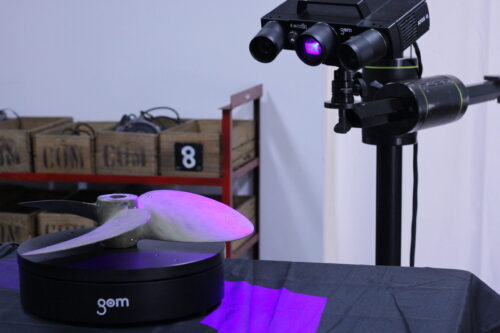

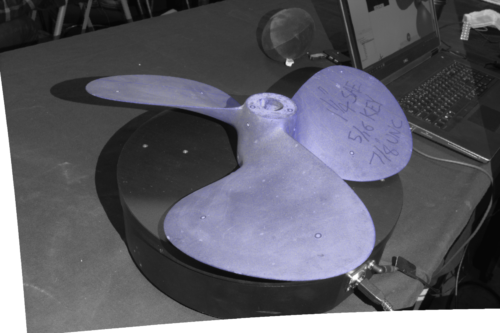

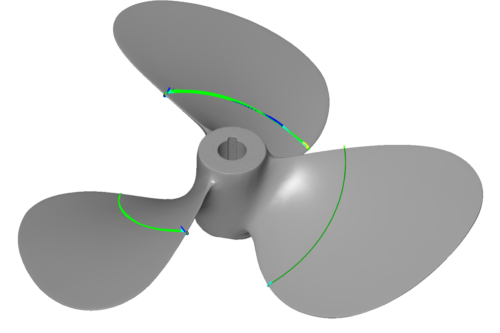

For the purpose of this project, we acquired a worn alloy boat propeller. The part had a few visible nicks and dents and some corrosion around its mounting hole. It is a common propeller type and state that our customer might see in a maintenance application and therefore ideal for our purposes. Due to the matte surface finish, the component did not require scanning spray to collect accurate data.

Marine Propeller 3D Scan Results

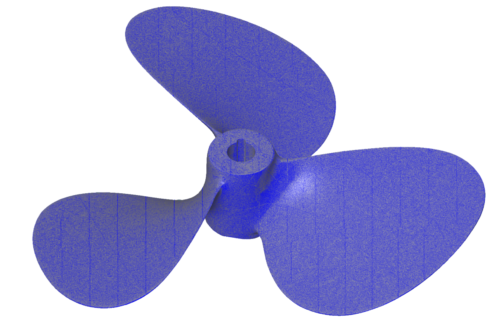

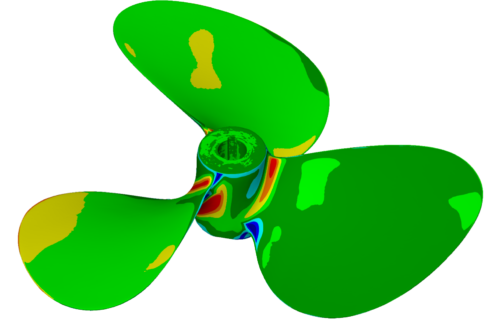

Using the ATOS Q‘s captured data, GOM Suite harmonizes the scans using the surface dots as reference geometry and automatically creates a precise STL mesh of the component. The result is an accurate digital twin of the propeller which can then be used to measure and analyse any of the part’s features or defects. This digital twin can also be transformed into CAD data which can be use for tasks such as propeller performance or pitch verification, manufacturing of a new propeller based on the existing part, or repair & service work. Take a look at the photos below showing some of the scan data and analyses performed. For full details, download the inspection report using the form at the bottom of the page.

Download Marine Propeller Inspection Report

Interested in reading about our next projects and company news?

Subscribe