25 Aug GOM Scan 1 3D Scanner Demonstration

Introduction to GOM Scan 1

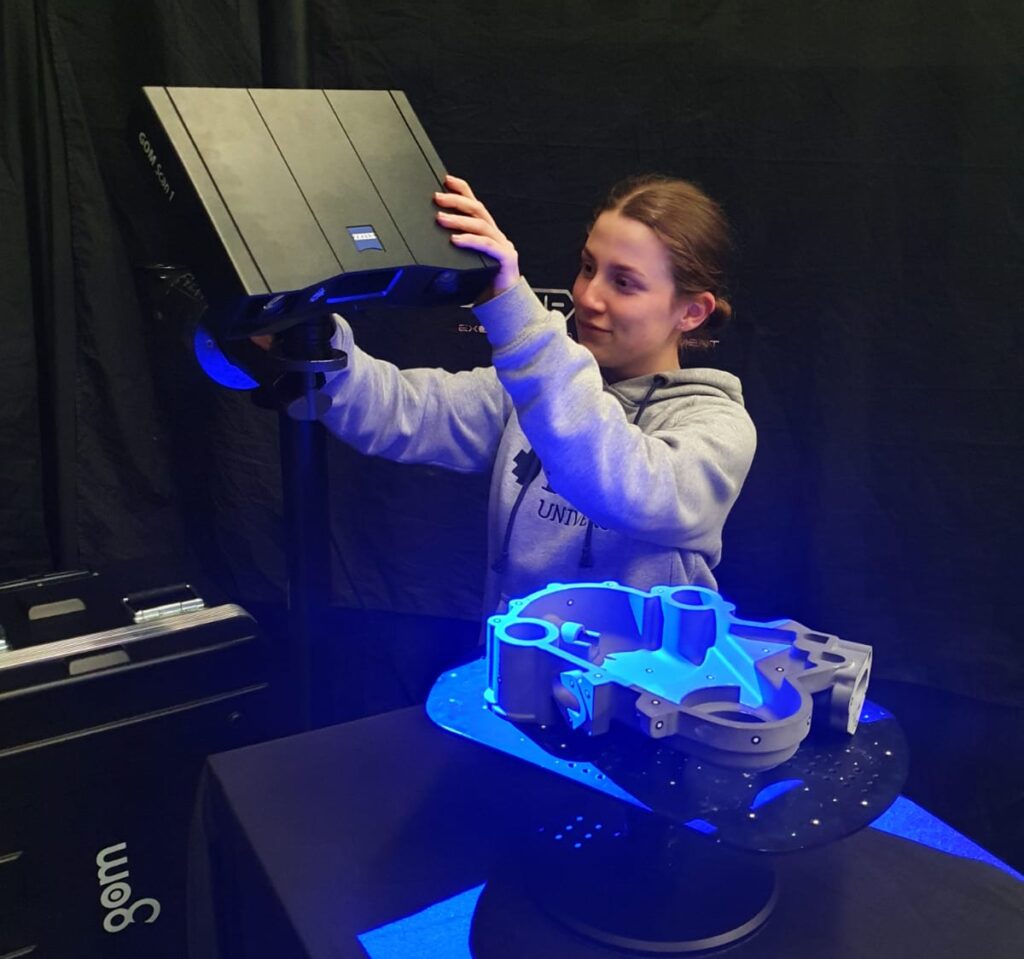

3D optical scanners have become commonplace in design and engineering studios as well as in production environment for quality control. They utilise light emitters or lasers to project partners onto surface. Sophisticated cameras capture images of these patterns and use them to create 3D models in record time of the object. The GOM Scan 1 is designed for businesses who are price-conscious but still looking for technology enabling a high level of precision. It is portable (weighing in at only 2.5kg), easy to use and integrates with GOM Inspect software allowing you to inspect parts, perform analyses and reverse engineer CAD models.Scanning Methodology

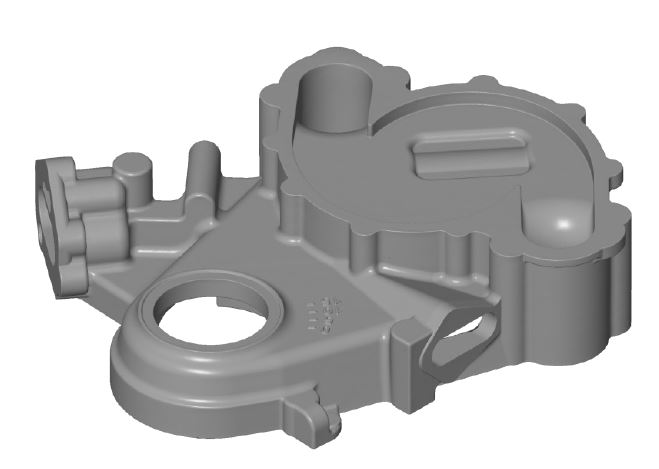

We selected a 3D printed polymer part approximately 300x300mm in size. The part had a number of common features you may want to measure on objects or components such as mounting holes, curved surfaces and strait edges.

We performed a full scan of the part using reference markers (dots) placed on the part and on the manual rotation table used for the scan. The GOM Scan 1 was mounted on a studio stand and no automation was used. The room was kept at ambient temperature and regular lighting to simulate an office or shop-floor environment. The 3D scan was performed by taking a several snapshots of each side which are then automatically analysed and combined in GOM Inspect to produce an accurate digital model. From start to finish, the scan and rendering of the 3D model took just under 25 minutes.

We selected a 3D printed polymer part approximately 300x300mm in size. The part had a number of common features you may want to measure on objects or components such as mounting holes, curved surfaces and strait edges.

We performed a full scan of the part using reference markers (dots) placed on the part and on the manual rotation table used for the scan. The GOM Scan 1 was mounted on a studio stand and no automation was used. The room was kept at ambient temperature and regular lighting to simulate an office or shop-floor environment. The 3D scan was performed by taking a several snapshots of each side which are then automatically analysed and combined in GOM Inspect to produce an accurate digital model. From start to finish, the scan and rendering of the 3D model took just under 25 minutes.

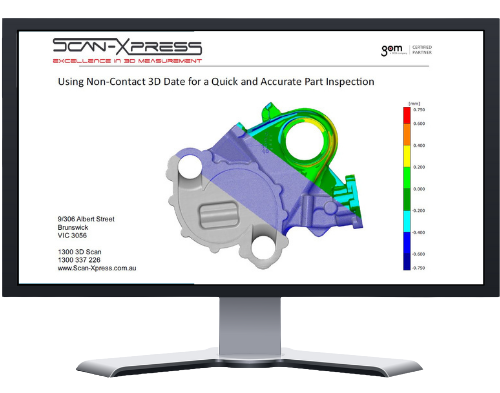

3D Inspection & Quality Control Sample Report

GOM Inspect allows you to quickly perform GD&T analyses, CAD comparisons and export mesh data to usable 3D CAD formats. Complete the form below to download a copy of the demo report:

Interested in reading about our next projects and company news?

Subscribe