02 Dec Automotive Reverse Engineering

We were contacted by an automotive enthusiast to perform a reverse engineering & design project on a Ford Falcon hood scoop. Using 3D scanning, we were able to accurately create a digital twin and reverse engineer for production. We used our latest scanning solution – the GOM Scan 1 – to perform this project. Check out the video below for the full story.

Project Details

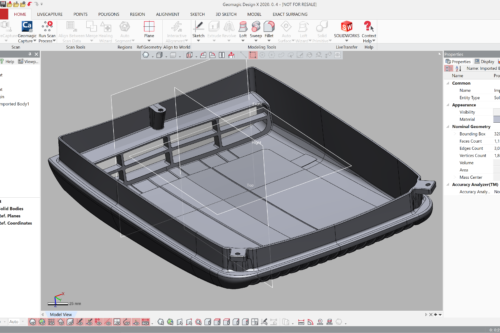

Our customer shipped us the Ford Falcon hood intake in question. The assembly featured 2 separate components that our customer wanted to have redesigned into one. Due to the matte surface finish, the component did not require scanning spray to collect accurate data.

For the 3D scan, we used the GOM Scan 1 in conjunction with the ROT 350 automated rotation table. The GOM Scan 1 is a highly versatile sensor built for industrial applications where precision is critical. It captures up to 6 million points per scan creating accurate digital twins usable for reverse engineering or quality inspection. The ROT 350 automated rotation table helped us speed up the scanning process but would not be required to operate the GOM Scan 1. The scan took approximately 10 minutes to complete using this set up.

3D Scan & Reverse Engineering Results

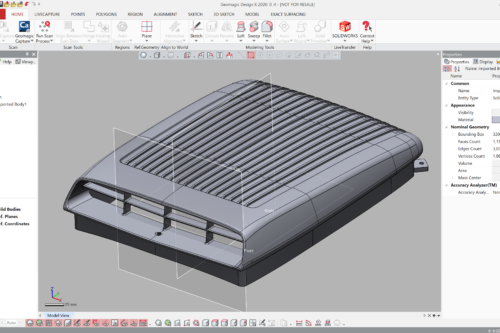

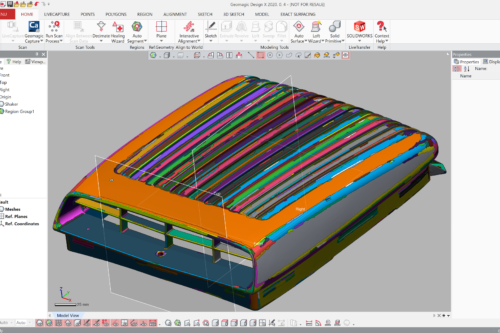

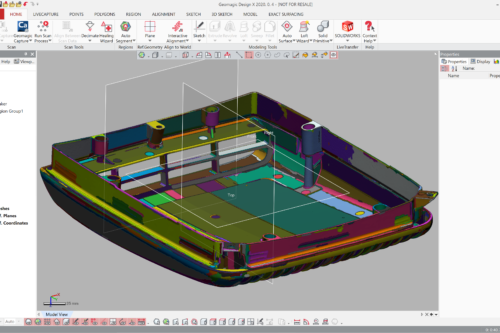

Using the GOM Scan 1‘s captured data, GOM Suite harmonizes the scans using the surface dots as reference geometry and automatically creates a precise STL mesh of the component. The result is an accurate digital twin of the hood scoop which can then be used to create a CAD model. We used Geomagic Design X to create a CAD model. Geomagic matches geometric features to scan surface data in order to arrive at a usable CAD model closely based on the object’s digital twin. Take a look at the photos below showing some of the scan data and CAD conversion.

Interested in reading about our next projects and company news?