19 Jan ARAMIS for Materials Testing at Deakin University

One of our long time partners – the Deakin University Institute for Frontier Materials (IMF) – recently purchased a second ARAMIS 3D camera system to use for digital image correlation (DIC) in their state of the art materials testing facility.

The IFM is a research centre specialising in materials research and testing. Their mission is to lead and inspire innovations in materials science and engineering that have a transformational benefit to society.

Watch the short video below for a full story covering the type of work performed by the IFM benefiting global manufacturing as well as how ARAMIS helps them achieve their mission.

Digital Image Correlation Requirements

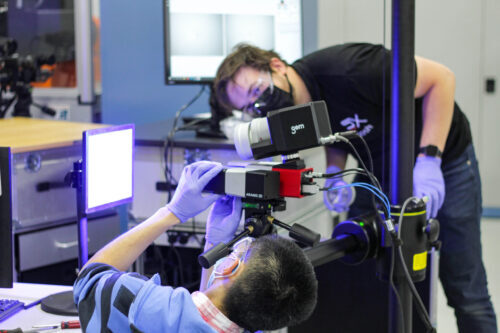

The staff at the IFM was looking to increase their research throughput capabilities. Having purchases an ARAMIS adjustable system in 2014 to perform stress/strain materials testing; this system was often booked out by the numerous graduate students and researchers using it in their day to day. They needed a second system to keep up with the demand that could perform various digital image correlation with flexibility and speed.

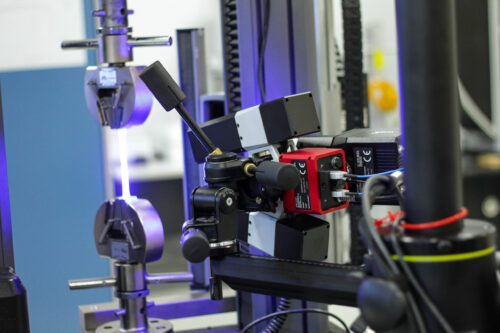

The selected system was the ARAMIS fixed 3D camera system since it requires minimal adjustment and calibration time is greatly reduced compared to the adjustable version. The IFM chose to purchase two lenses, the 35mm and the 180mm, allowing them to precisely measure samples both large and small.

ARAMIS and GOM Corelate: a solution for research & industry

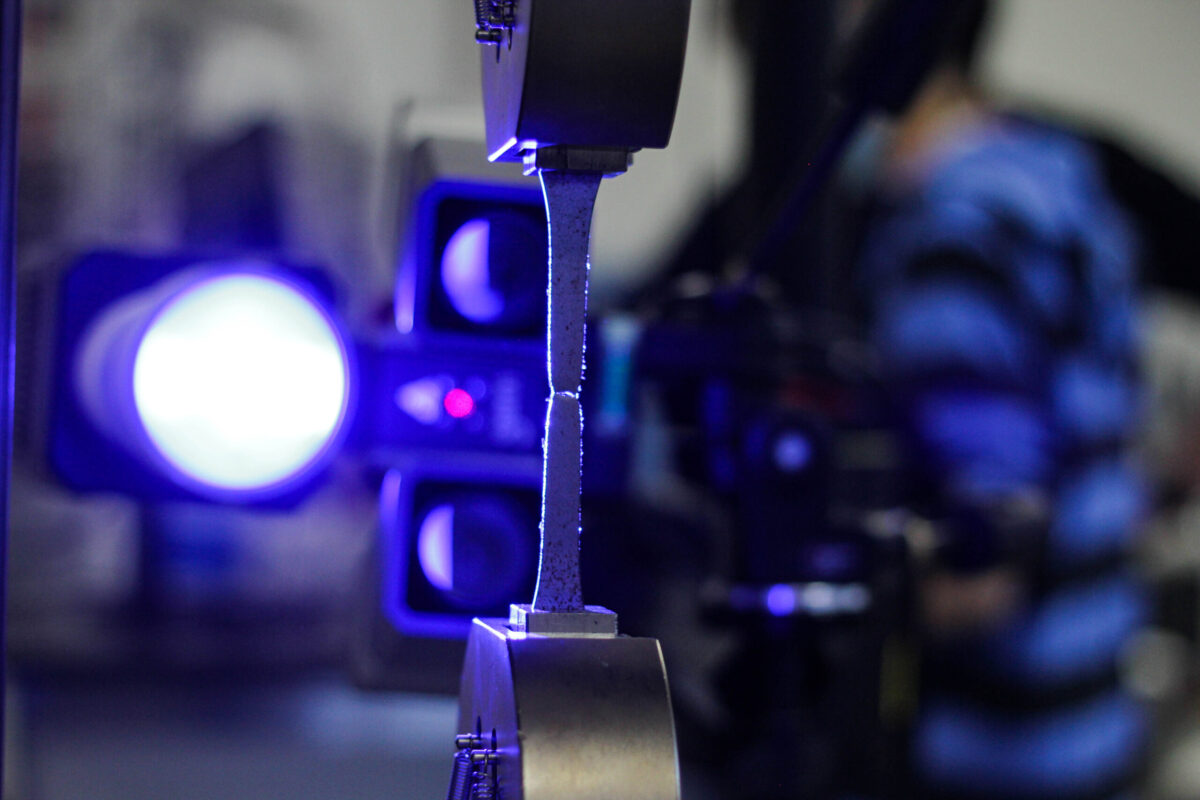

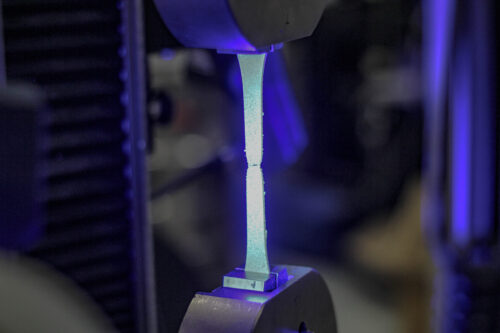

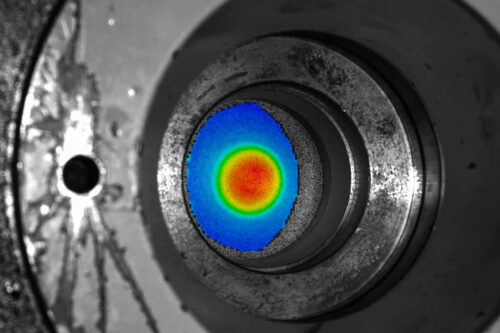

The ARAMIS 12M captures images as speeds ranging from 25-100 fps with a maximum resolution of 12 megapixels. This makes it ideal for the precision requirements of alloy and metal sample testing. At the IFM, the ARAMIS system is primarily used for measuring deformation across tensile samples or during punch testing such as the Marciniak test shown below. It is also used to produce form limit curves (FLC) for sheet metal forming applications. The research findings are used by the IFM’s international partners to design and manufacture strong, reliable and lightweight structures primarily in the automotive, rail and transportation industries.

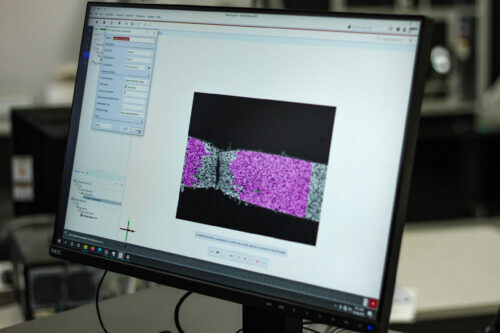

ARAMIS is a complete system which comes integrated with GOM Correlate software. The package allows for complete digital image correlation including evaluation of surface motion & deformation. Using stochastic patterns and/or reference point applied on the surface of the samples, GOM Correlate automatically recognises and tracks individual point movements with a high degree of precision. The software then allows full field or point based evaluation and reporting including stress/strain mapping, form limit curves, strain rates and net displacement.

Interested in reading about our next projects and company news?