12 Jul AESUB Spray Thickness Test

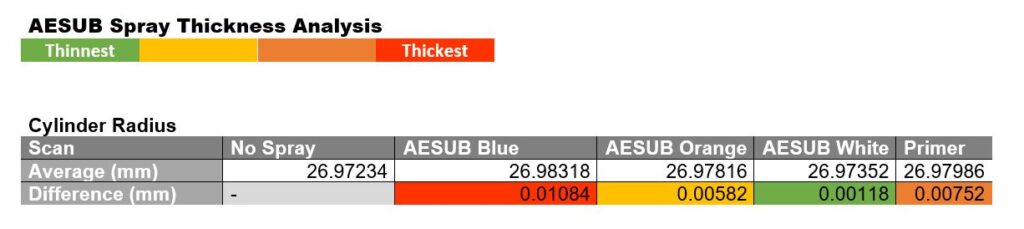

Objective: Perform an analysis of AESUB scanning sprays in order to determine approximate thickness values for future applications

In order to better understand and document the properties of AESUB Scanning Spray products, the Scan-Xpress team performed a test in order to determine approximate thickness of sprays applied on a smooth steel surface.

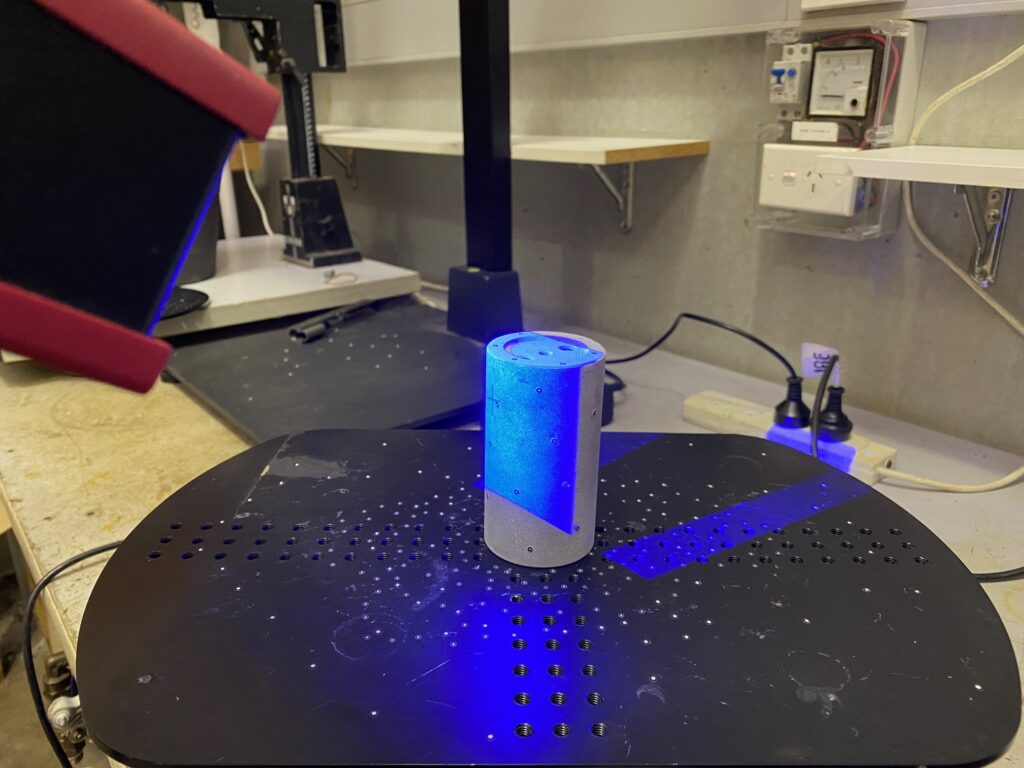

The ATOS Core 3D scanner was used for conducting this test due to its high accuracy when measuring small volumes.

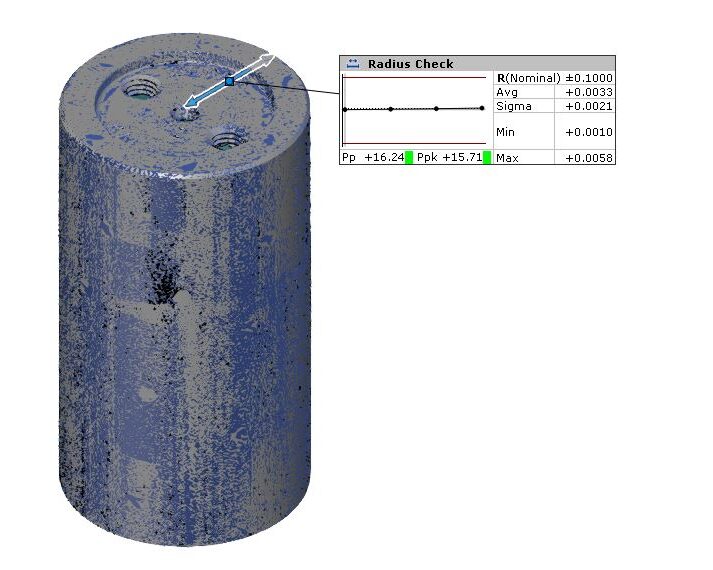

We performed full-field 3D scan of a steel cylinder (above left) and compared the data with a 3D scan of the same cylinder with each AESUB scanning spray applied to the surface (above right).

We performed 5 scans of each instance and used the average values generated for the series to compare the cylinder radius values allowing us a determine an approximate spray thickness. The GOM scanning software‘s imbedded geometry alignment function was used to generate a best-fit cylinder for each scan which provided us with an accurate radius measurement. Shown above are scans and radius best-fits for the naked cylinder (left) vs. the AESUB blue sprayed cylinder (right).

Results:

Our team will use this data to better account for the effects of AESUB scanning spray application on part surface for future scanning projects. We also encourage our AESUB spray customers to make use of this data when performing their in-house scans. For details & advice please contact us.

Interested in reading about our next projects and company news?