10 Nov 3D Scanning Components of a Turbine Unit

Customer: Origin Energy

Objective: 3D Scan & analysis of turbine components for a maintenance and repair project

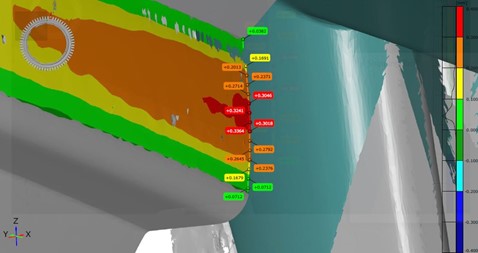

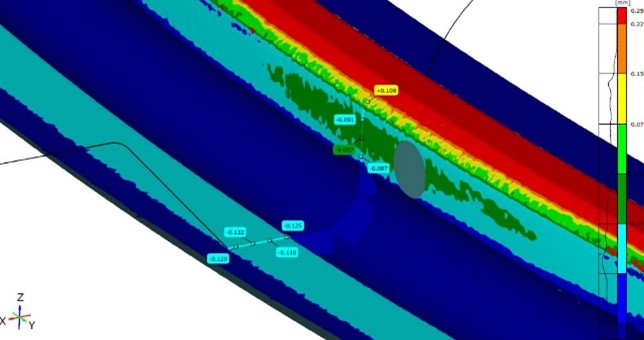

An issue had occurred during the operation of an Origin Energy turbine unit. The L-RING and the DISC had slipped out of their secured positions causing damage to critical surfaces. To be able to repair the disc, it was proposed to machine back the affected surfaces.

The client anticipated the areas of greatest damage would be close to the locking pins. One of the pins had been completely severed by the force. Scan-Xpress was hired to perform a 3D scan on the 2m diameter Disc and L Ring in order to assess the damage and enable the service team to complete their work.

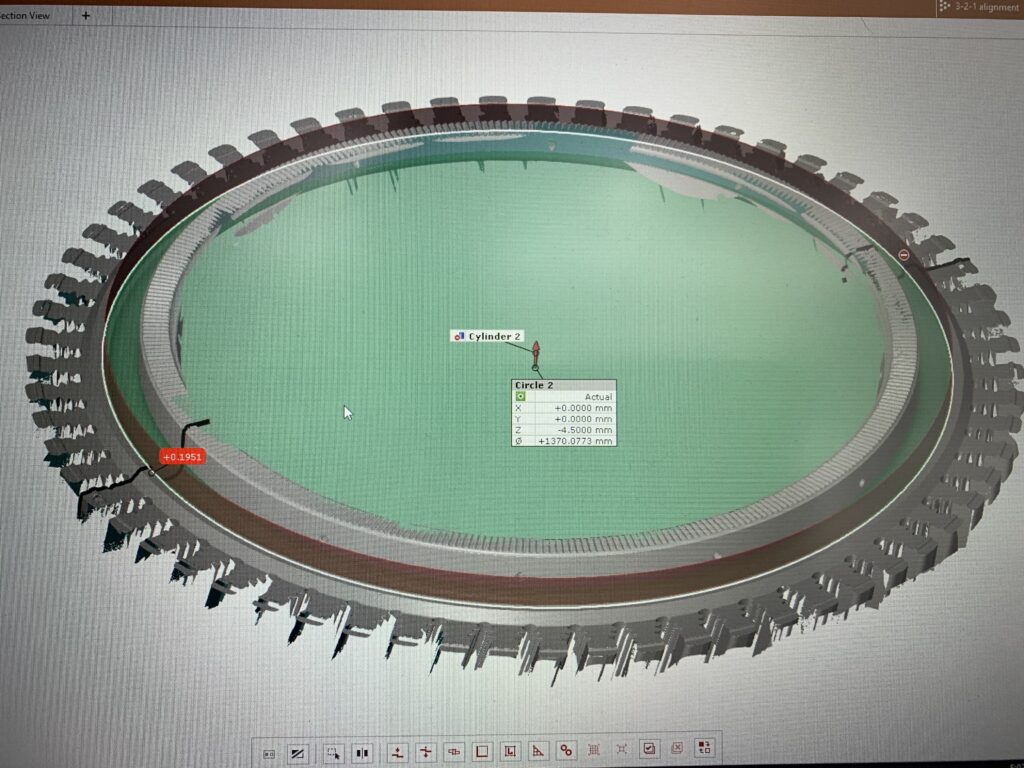

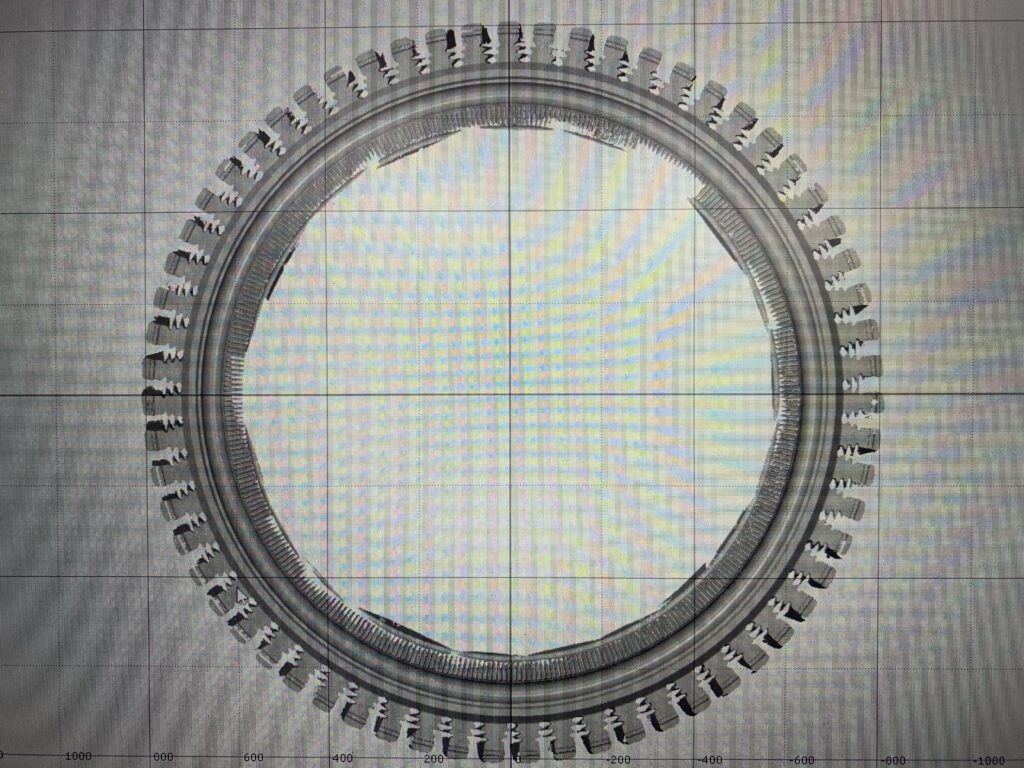

The project involved two discreet studies at different physical locations. These included the DISC located in regional Victoria (above left) and the L-RING located in Melbourne (above right). The goal was to scan both the parts and establish whether sufficient material remained in the disc to allow for re-machining of the critical surfaces without compromising the integrity of the part.

To achieve accuracy over the entire part a photogrammetric study was first conducted using the Tritop system. This process produced a high accuracy point cloud of the reference dots attached to the DISC and L-RING providing a reference grid for measurement with an accuracy of 20 microns.

The ATOS Q sensor was then used to captured high resolution localized scan patches defining features in great detail and with great accuracy. A 270mm measurement volume set-up was used producing 12 million points per scan area.

The rendered results included colour maps showcasing high and low areas on the surfaces as well as nominal to actual dimensional checks. The forces causing the movement of the two pieces were unknown and damage had occurred to both parts. Having data on both the disc and the L Ring enabled us to create a virtual assembly and conduct a simulation of their fitment to help better understand what had taken place. The conclusions drawn from this analysis enabled Origin Energy to assess the damage and perform the required service work to get the turbine operational.

Interested in reading about our next projects and company news?