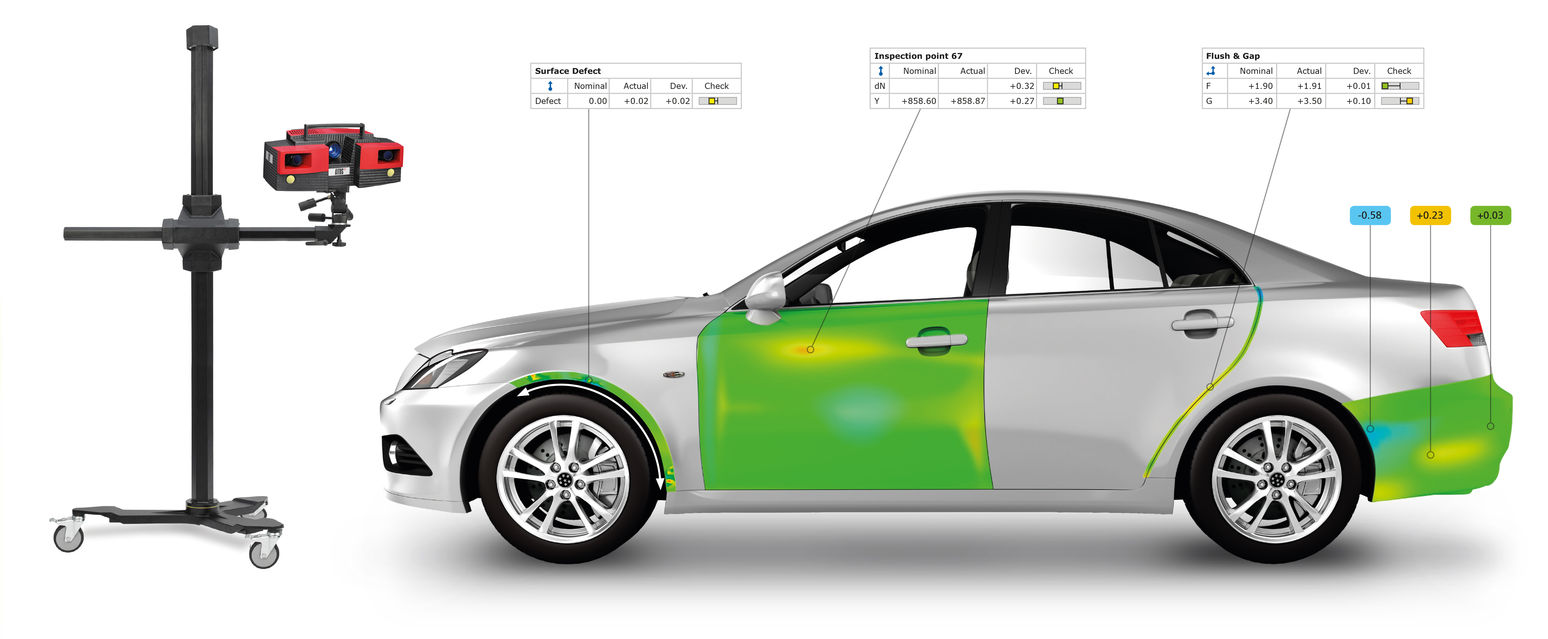

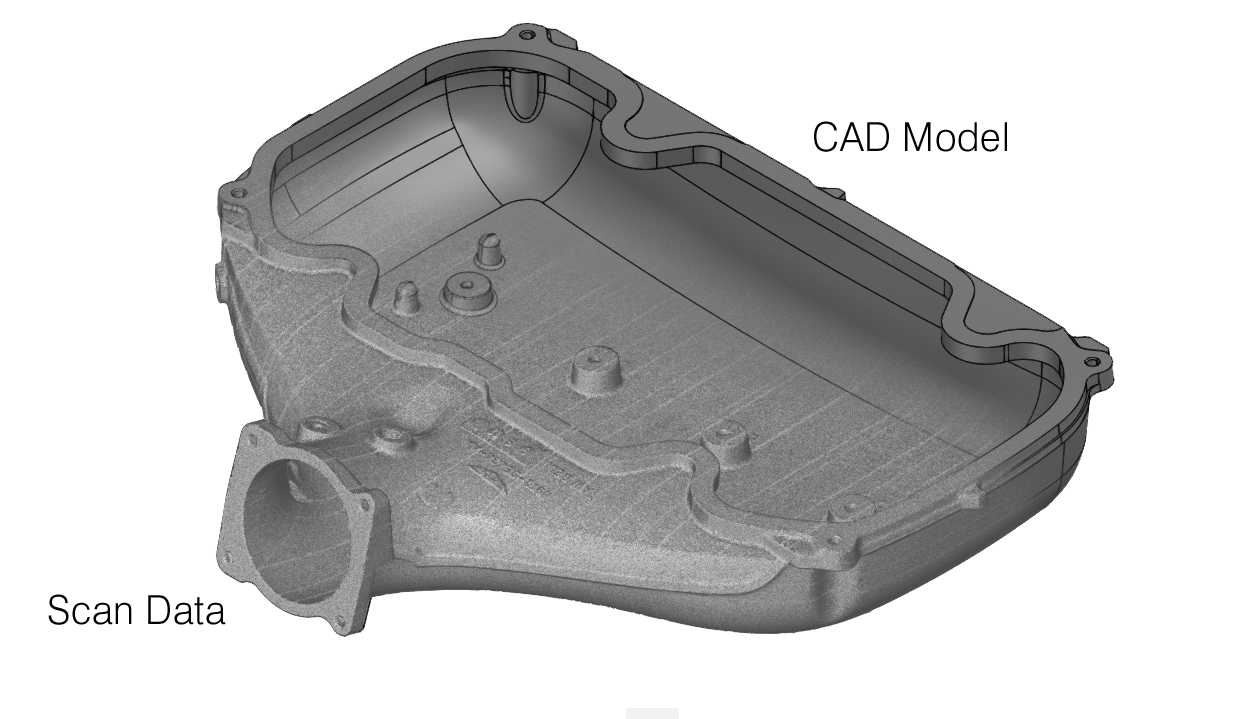

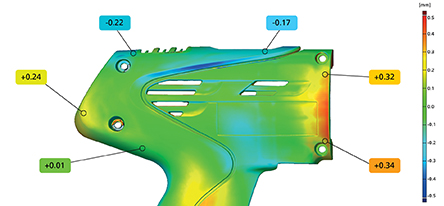

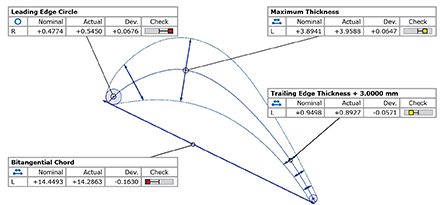

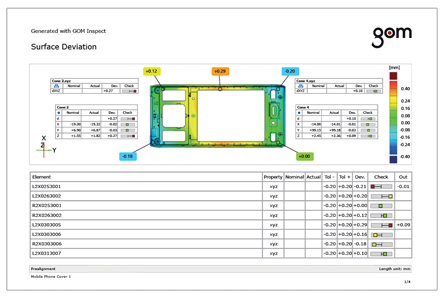

Using our market leading GOM Inspect Software, we can offer various inspection services for optical and probe measurements. By comparing 3D scan data to the CAD model, we can perform geometric comparisons on surfaces, holes, curves and 2D sections to support your quality control requirements. Inspection can also be conducted by anyone using the free GOM Inspect – industry standard inspection software.