Leveraging modern metrology solutions and digital design techniques are key factors to success in the plastic injection moulding industry. Having access to accurate internal and external part 3D data will help you optimise your processes and ensure you are meeting your tolerance and quality objectives.

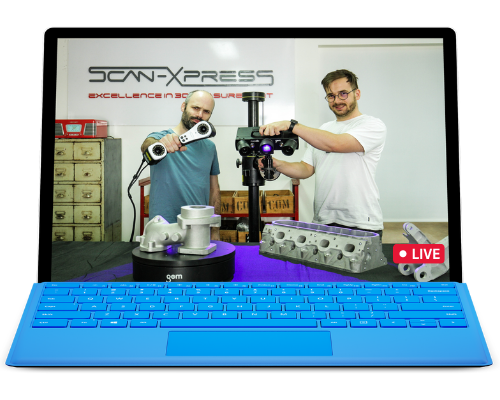

Below you can find out more about how Scan-Xpress can assist plastic injection moulding manufacturers design new products and moulds more efficiently, save money and time throughout the product lifecycle and improve plastic part final quality.

Use 3D scanning to capture accurate digital twins of prototypes or production parts, compare to or reverse engineer CAD data, and quickly perform quality checks or design iterations. Optical metrology offers benefits in time and dollar savings by enabling full field data capture and automated inspection functionalities.

Using revolutionary ZEISS Reverse Engineering (ZRE) software, you can save time and money by cutting down on mould design iterations. ZRE uses plastic part 3D data – captured on a 3D scanner or CMM – and design CAD data to predict tool compensation changes required to achieve the desired result.

Use computer tomography and X-Ray measurement machines to perform 3D measurement and inspection jobs effectively –

detecting both internal and external defects non destructively. ZEISS CT and X-Ray therefore help you to achieve sustainable quality improvement in the manufacturing of plastic parts.

Plastic parts are becoming more complex with small manufacturing tolerances and requirement for short time to market. Respond to these challenges using GOM 3D scanners and optical metrology tools which provide you with a solution for fast and efficient inspection of tools, first articles and final plastic parts.

Want to book a demo or discuss your project?

Featured Plastic Injection Moulding Applications

Eliminate Warpage in Plastics Quality Control

Annoyed about plastic warpage and how it makes quality control of unassembled parts difficult? With the GOM Inspect Pro De-warp function, 3D scanned plastic parts can be virtually assembled, allowing you to check their dimensions in a realistic environment.

Quality Inspection in Medical Plastic Injection Industry

iMARK Molding, in Woodville, Wisconsin, manufactures product plastic components for the medical device industry. They use several ZEISS systems to perform their quality inspection including an O-Inspect VMM, CONTURA CMM and a METROTOM X-Ray system.

Plastic Consumer Goods Design & Prototyping

The Scan-Xpress team was contracted to design and execute a usable prototype of a reusable plastic coffee cup for a Melbourne based start-up. To accomplish this, we used 3D scanning, reverse engineering and 3D printing to deliver a great prototype in no time.

Plastics Packaging Quality Inspection us 3D Scanners

At Atka, it’s all about plastics and machines that attach non-manipulable plastic caps to beer kegs that are delivered to breweries all over the world. 3D scanning enables this family-run business to stay ahead of the game at all times.